Tubing Head Connector

Casing head connector is a connector used to connect cables or pipelines with different diameters. It usually consists of two casing heads and a connector.

The product material in this illustration is 4130. According to the drawings provided by customers, products under 6 meters and within 5 tons can be processed. The shell produced by our Baohua company is mainly used in the accessories of related equipment at the wellhead of oil fields.

Production advantages: die forging or free forging, from blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. The cost can be reduced.

Tubing connector is a tool to connect tubing and wellhead, which is usually used in oil exploitation and transportation projects. It connects tubing and wellhead closely to ensure the extraction and transportation of oil and gas resources. The tubing head connector is generally composed of two parts: the external thread of tubing thread and the internal thread of wellhead thread.

| NAME | Tubing Head Connector |

| MATERIAL | 4130-75K |

| HARDNESS | 207-237 |

| INNER DIAMETER | 65.41 |

| OUTSIDE DIAMETER | 504.95 |

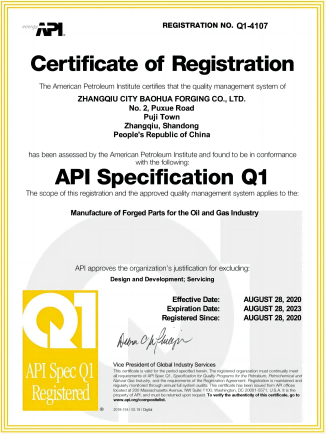

The tubing connector produced by our company is mainly used in oil field equipment accessories. Raw materials are purchased from round steel with recognized quality at home and abroad. We can forge the corresponding model of dies and hammers according to customers' requirements, thus improving production efficiency and saving time. At present, we have many types of materials such as: 42CrMo, 45#, 35CrMo, 4140, 4130, etc. After repeated pre-forging and die forging, the tubing connector has high forging ratio and good durability, which is suitable for key accessories of equipment in many industries.

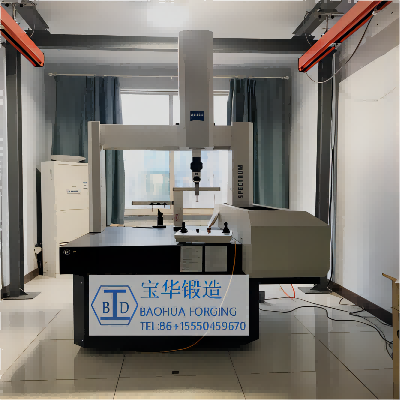

At present, our forging equipment in Baohua Company mainly includes: five tons and three tons of free forging hammers, 2500 tons, 1000 tons and 600 tons of friction presses, six large plywood hammers and various types of air hammers; There are more than 60 sets of machining equipment, including CA5116E*1015 vertical lathe, CW61100B and CW50 lathe. There are 2 sets of well-type and trolley-type electric furnaces for heat treatment. There are two tempering furnaces, which can complete product normalizing, annealing, tempering and other technological treatments. Equipped with a nationally recognized physical and chemical laboratory, the main testing equipment is a spectrometer imported from Germany with a value of nearly 500,000 yuan; Brinell hardness tester imported from the United States with a value of 120 thousand yuan can carry out ultrasonic nondestructive testing and mechanical performance test.

For details, please contact us by email. zhangqiubaohua@126.com

For details, please contact us by email. zhangqiubaohua@126.com

Related News

Submitted successfully

We will contact you as soon as possible