Casing Head On Sale

Casing head refers to a special short joint which is connected with the top of casing string by screw thread or flange and located in the outer casing when drilling on land or sea, and is used to support and fix casing string and other wellhead devices when drilling on land or sea.

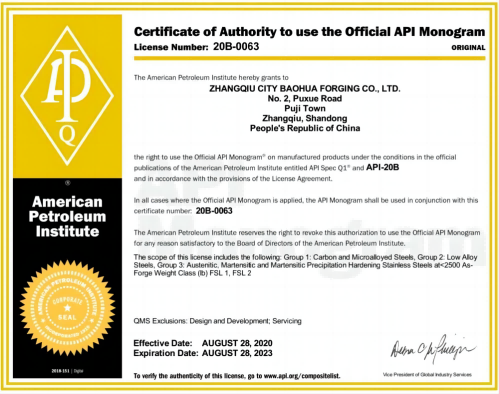

Advantages: The production of casing head has to go through a series of processing such as casting blank, rough cutting, fine turning, boring, drilling, heat treatment, quality inspection, etc. We process casing head in different stages according to customer requirements. And there are API certificates recognized by american petroleum institute, and the quality can be guaranteed.

Our company can independently design and process forging dies according to the drawings, and will try our best to save forging materials. The weight of the forged product can reach 60kg-5000kg, and the forging needs to be completed through heating, pre-forging, forming and other processes. Various materials including 42CrMo, 4140, 4130, 40Cr, 20CrMnMo, 18CrNiMo7-6, 410SS can be forged. Our company has API certificate and SQ1 certificate and has many years of experience in petroleum product processing.

The casing head is usually made of 35 or 42 Cr Mo alloy structural steel. There is also a casing hanger in the casing head, which is used to hang the casing string of corresponding specifications and seal the annulus. BOP stack shall be installed on it. After the well is completed, the Christmas tree is installed on the casing head.

The production of casing head generally includes the following process flow:

1. Blank casting: casting materials into workpieces.

2. Rough machining, that is, preliminary cutting of workpiece blanks.

3. Finish turning: use the lathe to process the rough cutting workpiece to the design accuracy.

4. Bore the diameter, and use the boring machine to bore out the designed inner diameter.

5. When drilling, the external connecting bolts of the drill are drilled out.

6. Heat treatment: quenching and tempering the workpiece.

7. Inspection and test: the geometric dimension, hardness, roughness, internal and external defects of the finished casing head shall be inspected and NDT shall be carried out.

Welcome to ask for price online or by email.