Sales Tubing Head Connector

Tubing connector is a tool to connect tubing and wellhead, which is usually used in oil exploitation and transportation projects. It connects tubing and wellhead closely to ensure the extraction and transportation of oil and gas resources. The tubing head connector is generally composed of two parts: the external thread of tubing thread and the internal thread of wellhead thread.

Our advantages: low price, high quality and mass production.

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad. The company has its own technology research and development organization "Zhangqiu Baohua Forging Technology Development Center".

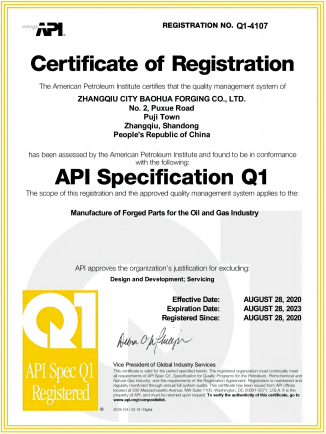

The company's main management, technical personnel and key equipment operators have more than 15 years of working experience in the same industry. And since 2001, the company has successively passed ISO9001, ISO14001 and APIQ1, and obtained the "Special Equipment Manufacturing License".

The tubing head connector has the characteristics of high strength, corrosion resistance and tight connection. Our company can independently design molds and forge them according to product specifications. Material type and weight can be made according to customer's requirements. This kind of tubing connector is a die designed by our company independently according to the requirements of customers, which can realize precision forging and make the material utilization rate reach over 90%, thus greatly saving the cost. In addition, our company also has rough machining, heat treatment and finishing, which can be delivered under different delivery conditions according to customer requirements, saving time and cost. As for equipment, our company has more than 80 different processing machinery and equipment, as well as inspection and testing equipment such as Zeiss CMM, Japanese small board profiler, gear detector and Omega tool alignment detector.

Welcome to online consultation.