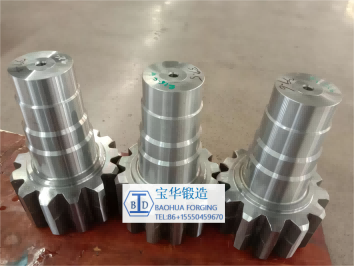

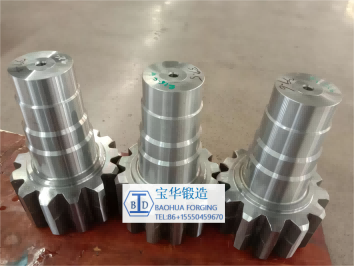

Output Gear Shaft

The output gear shaft produced by our company is mainly used for the equipment used in the wind power industry.

For the production of the output gear shaft, we can independently design the mold according to the drawings provided by customers, and form it in one step to realize mass production and improve production efficiency.

Our manufactured output gear shaft can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials according to customer requirements. Forging can be carried out on different forging equipment units according to different weights. The forged product can weigh up to 6kg-500kg. The forging process needs to be completed by heating, pre-forging, forming and trimming. All these processes are integrated by our Baohua Company, thus ensuring the quality of products.

In the design, the application of gear shaft generally involves the following situations:

1. The gear shaft is usually a pinion (a gear with fewer teeth).

2. The gear shaft is generally at the high speed stage (i.e. low torque stage).

3. The gear shaft is rarely used as a sliding gear for speed change. It is generally a fixed running gear. First, because it is at a high speed, it is not suitable for sliding speed change.

4. The gear shaft is a combination of shaft and gear. However, during design, the length of shaft should be shortened as much as possible. Too long shaft is not conducive to upper gear hobbing, and the support of shaft is too long, which causes the shaft to thicken and increase the mechanical strength (such as rigidity, deflection, bending resistance, etc.).

Welcome new and old customers to inquire about the price. We will reply to your email or message in time.