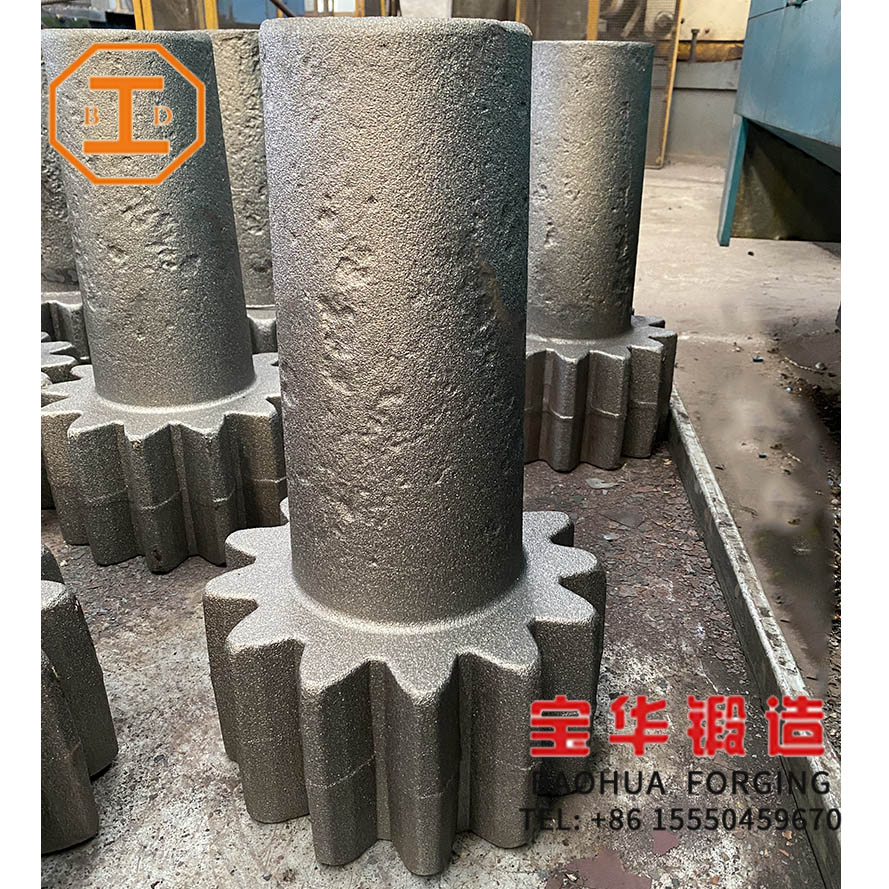

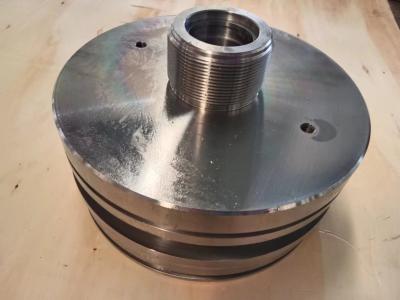

Output gear shaft, according to customer requirements can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials, according to the weight of different forging equipment units for forging, the weight of forged products can be To reach 6kg-500kg, forging needs to be completed through heating, pre-forging, forming, trimming and other processes.

Customers in any industry using output gear shafts can request a quote for any quantity of forged gear shafts, from one prototype at a time and small batches to high volume production. Our extensions include gear cutting to finished gear size.

A gear shaft is a mechanical part that supports rotating parts and rotates with them to transmit motion, torque, or bending moment. It is generally in the shape of metal rods, and each segment can have different diameters. The rotating parts of the machine are mounted on the shaft.

In the design, the application of gear shaft generally involves the following situations:

1. The gear shaft is usually a pinion (a gear with fewer teeth).

2. The gear shaft is generally at the high speed stage (i.e. low torque stage).

3. The gear shaft is rarely used as a sliding gear for speed change. It is generally a fixed running gear. First, because it is at a high speed, it is not suitable for sliding speed change.

4. The gear shaft is a combination of shaft and gear. However, during design, the length of shaft should be shortened as much as possible. Too long shaft is not conducive to upper gear hobbing, and the support of shaft is too long, which causes the shaft to thicken and increase the mechanical strength (such as rigidity, deflection, bending resistance, etc.).