On Sale Threaded Flange

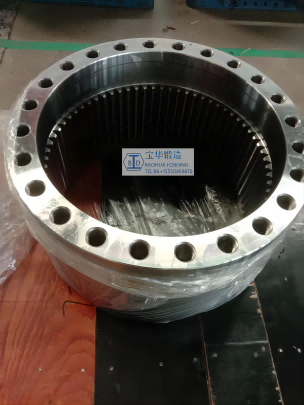

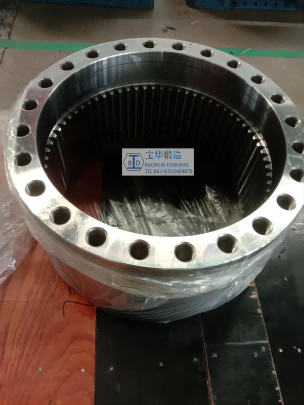

The production of flange has to go through a series of processing such as casting blank, rough cutting, fine turning, boring, drilling, heat treatment, quality inspection, etc.

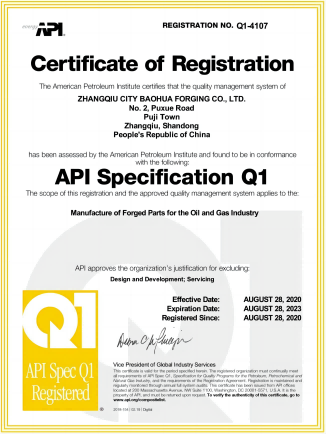

We process the casing head products in different stages according to the requirements of customers. And there are API certificates recognized by american petroleum institute, and the quality can be guaranteed. The flanges we process and produce are mainly used in petroleum and construction machinery and equipment industries. The materials used in processing are flexible and can be cast according to the shape and size provided by customers.

According to customer requirements, 4140, 4130, 45 #, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials can be made. Forging can be carried out on different forging equipment units according to different weights. The weight of forged products can reach 6kg-2000kg. Forging needs to be completed through heating, pre forging, forming, trimming and other processes to increase the forging ratio and stability of products. Flange forgings can be finished to meet the final assembly conditions.

Threaded flange refers to a kind of flange which is connected with pipe by thread. During design, loose flange can be used. The advantage is that no welding is required, and the additional torque generated to the cylinder or pipe when the flange is deformed is very small. The disadvantage is large flange thickness and high cost. It is applicable to the connection of high pressure pipes.

The threaded flange is a non welding flange, which processes the inner hole of the flange into pipe thread and connects it with the threaded pipe. Compared with flat welding flange or butt welding flange, threaded flange has the characteristics of convenient installation and maintenance, and can be used on some pipelines that are not allowed to be welded on site. Alloy steel flange has sufficient strength, but it is not easy to weld, or the welding performance is poor, and threaded flange can also be selected. However, when the pipe temperature changes rapidly or the temperature is higher than 260 ℃ but lower than - 45 ℃, it is recommended not to use threaded flanges to avoid leakage.

Customers in any industry of flanges can request quotations for any number of flanges, from one prototype at a time and small batch to large batch production.