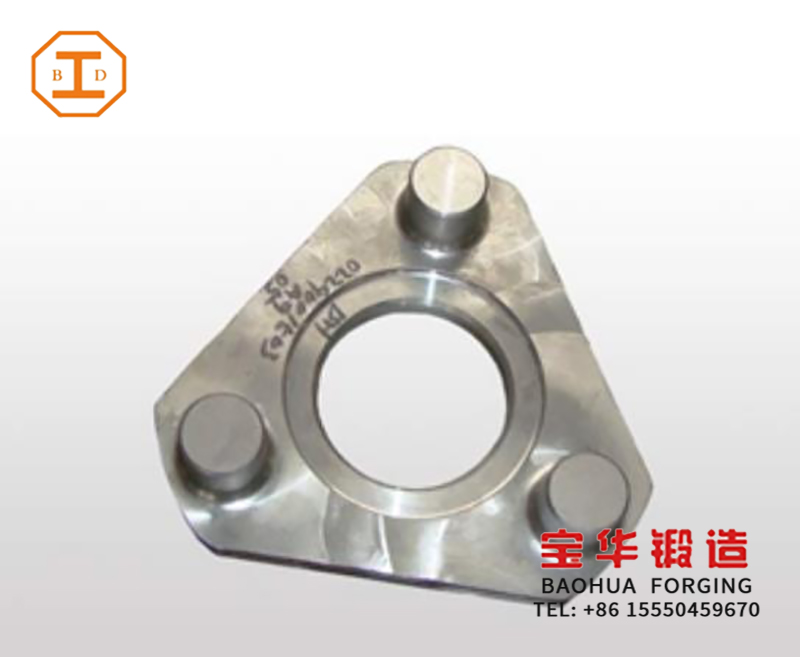

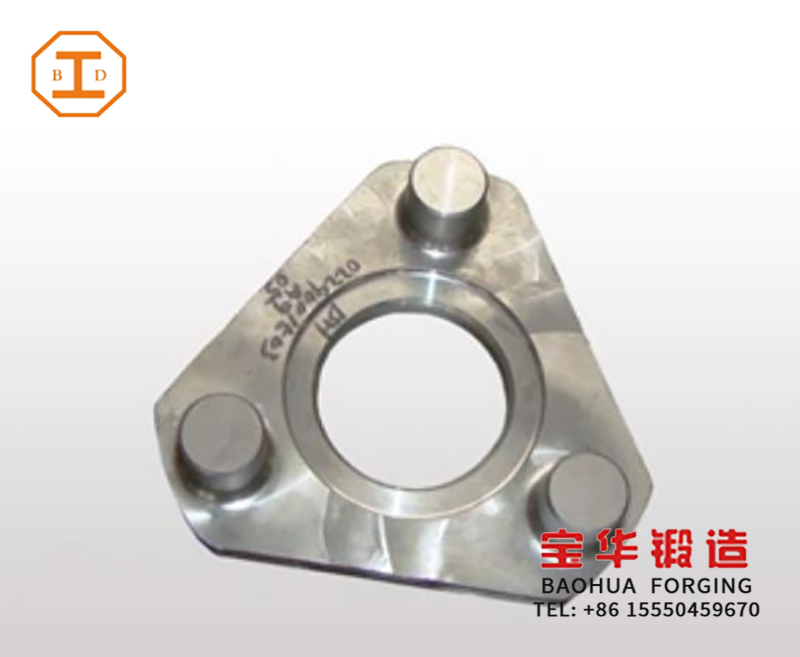

Our company can independently design and process forging dies according to the drawings, and has many years of experience in forging planetary carriers. The weight of the forged planet carrier product can reach 6kg-400kg, and the forging needs to be completed through heating, pre-forging, forming, trimming and other processes. Various materials including 42CrMo, 4140, 4130, 40Cr, 20CrMnMo, 18CrNiMo7-6, 410SS can be forged.

Planetary gear means that the rotation axis is not fixed, and it is installed on a rotatable bracket (blue) (the black part in Figure 1 is the housing, and the yellow part is the bearing). In addition to the planetary gears (green) rotating around their own rotating shafts (B-B) like fixed shaft gears, their rotating shafts also rotate around the axis (A-A) of other gears with the blue bracket (called planetary carrier). The rotation around its axis is called "rotation", and the rotation around the axis of other gears is called "revolution", just like the planets in the solar system, hence the name.

The planetary gear mechanism is divided into single planet row and double planet row according to the different groups of planetary gears installed on the planet carrier.

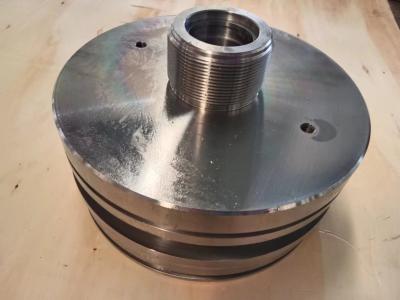

In the 1970s, induction hardening was used in the roll manufacturing. At first, power frequency power supply was used. Later, dual power frequency was used, that is, two power frequency induction coils were used to heat the roll twice continuously to ensure the uniformity of the depth and temperature of the heating layer. Later, dual frequency induction heating appeared, that is, a power frequency induction coil and an intermediate frequency induction coil were used to heat the roll successively.

Customers in any industry using forgings can request a quote for any quantity of forgings, from one prototype at a time and small batches to high volume production. Our extensions include gear cutting to finished gear size.