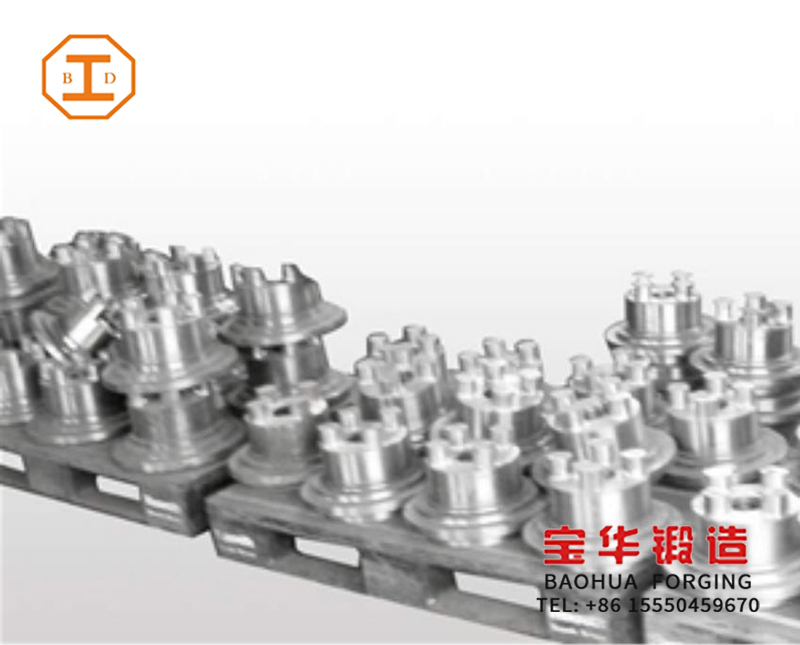

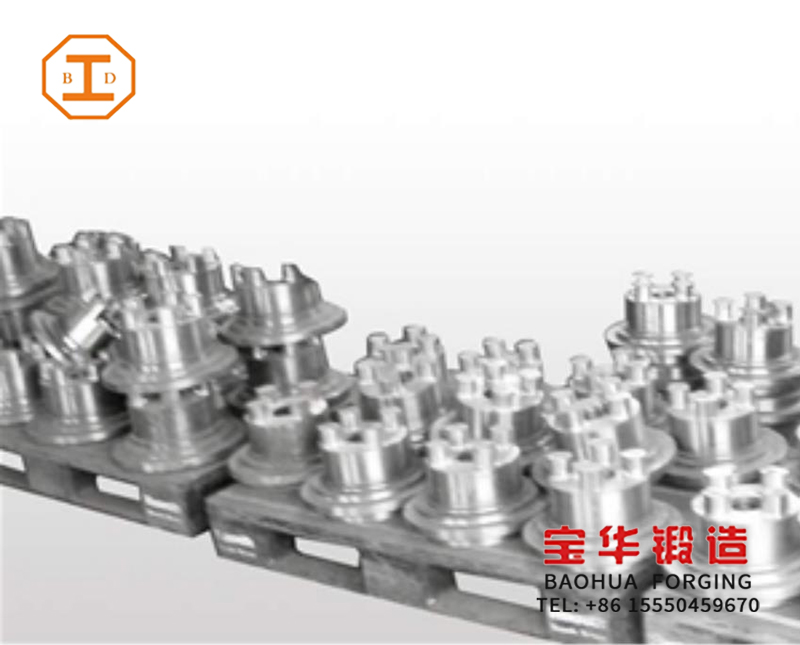

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 15kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.

The Supporting Shaft Component Structure and bobbin collet shaft device of filament winding machine discloses a supporting shaft component structure and bobbin collet shaft device of filament winding machine. The supporting shaft component structure comprises a supporting shaft main body which is an axially through hollow shaft;

The side wall of the cantilever cavity of the driving shaft is provided with an air inlet passage and an air outlet passage; The air inlet channel is far away from the rear end of the hollow shaft; The side wall of the hollow shaft is provided with a transmission channel; The drive shaft support cavity extends along the drive shaft cantilever cavity to the air inlet channel.

The bobbin chuck shaft device of the filament winding machine is provided with the supporting shaft assembly.

The invention can extend the drive shaft support cavity along the drive shaft cantilever cavity to the air inlet channel, the length of the drive shaft support cavity is extended, and a support can be added in the drive shaft support cavity to rotate the connection with the drive shaft. In this way, the rigidity of the drive shaft can be greatly improved. After the length of the drive shaft is increased and the length diameter ratio of the drive shaft is increased, the drive shaft still remains rigid enough to meet the process requirements of large package, multi head spinning and high-speed spinning.

Customers in any industry using support shafts can request a quote for any quantity of forged support shafts, from one prototype at a time and small batches to high volume production.