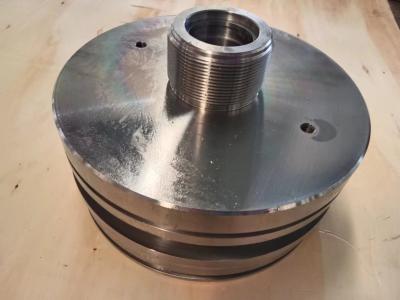

Sales Cylinder Head

The cylinder head manufactured by us is forged by double-die cavity, which saves material and improves machining efficiency.

For the production of cylinder head products, our company can forge and produce cylinder head products by using many kinds of materials, such as 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and so on, according to customer requirements. In addition, our company has independent research and development of double-die cavity forging process, which can greatly improve the forging efficiency and reduce the weight of blanking, and ultimately achieve the purpose of cost saving. According to the weight, forging is carried out on different forging equipment units. The weight of forged products can reach 6kg-500kg. The forging process includes heating, pre-forging, forming and trimming.

The cylinder head is a box shaped part with complex structure. The intake and exhaust valve seat holes, valve guide holes, spark plug mounting holes (gasoline engines) or fuel injector mounting holes are machined on them. The cylinder head is also provided with a water jacket, an air inlet and an exhaust port, and a combustion chamber or a part of the combustion chamber. If the camshaft is installed on the cylinder head, the cylinder head is also provided with a cam bearing hole or a cam bearing seat and its lubricating oil passage.

Bottom plane of cylinder head

Bottom plane of cylinder head [2]

The cylinder heads of water-cooled engines have three types of structures: integral, block and single. In a multi cylinder engine, if all cylinders share one cylinder head, the cylinder head is said to be an integral cylinder head; If there is one cover for every two cylinders or one cover for three cylinders, the cylinder head is a block type cylinder head; If each cylinder has one head, it is a single cylinder head. Air cooled engines are all single cylinder heads.