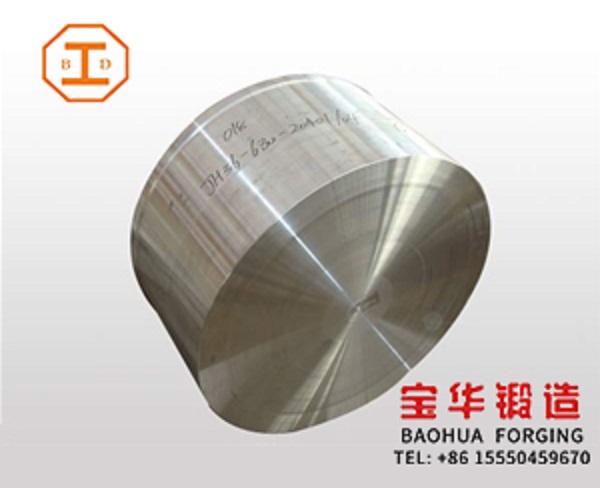

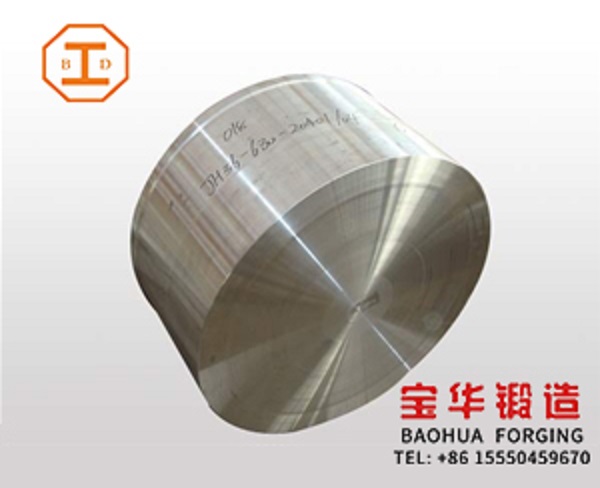

After heating and repeated forging, it may additionally be modulated and warmth dealt with and completed in keeping with purchaser requirements. After repeated forging, the forging ratio has excessive forging ratio and top durability, that's appropriate for key components of equipment. Our company can forge 10kg-5000kg forgings, and can forge a variety of materials including 42CrMo, 4140, 4130, 40Cr, 20CrMnMo, 18CrNiMo7-6, 410SS.

Gear forging products are mainly used in mining machinery, petrochemical, automobile manufacturing and other industries, of which more than 90% are automobile forgings, among which cold temperature precision forgings account for about 5.2% of the total forgings. In 2004, the total output of forgings in China was about 3.26 million tons, including 2.44 million tons of die forgings. Automobile forgings accounted for about 65% of die forgings, about 1.6 million tons, and cold temperature precision forgings accounted for about 4-5% of the total volume of automobile forgings. The forgings forged by free forging on hydraulic forging press with a capacity of more than 10MN are called large forgings, and the production industry of large forgings has reached a certain production scale and level.

The gear forging industry in China has achieved rapid development during the "Tenth Five Year Plan" period: in 2005, the annual output value of the gear industry increased from 24 billion yuan in 2000 to 68.3 billion yuan, with a compound annual growth rate of 23.27%. It has become the largest industry among China's mechanical basic parts. In terms of market demand and production scale, China's gear industry has surpassed Italy in the global ranking, ranking fourth in the world.

In 2006, the total industrial output value of all gear, transmission and driving parts manufacturing enterprises in China was 102628183 thousand yuan, an increase of 24.15% over the same period of the previous year; The accumulated product sales revenue was 9823824000 yuan, an increase of 24.37% over the same period of the previous year; The total accumulated profit was 5665210000 yuan, an increase of 26.85% over the same period of the previous year.

From January to December 2007, the total industrial output value of all Chinese gear, transmission and drive component manufacturers reached 136542841 thousand yuan, an increase of 30.96% over the same period of the previous year; From January to October 2008, the total industrial output value of all Chinese gear, transmission and drive component manufacturers reached 144529138 thousand yuan, an increase of 32.92% over the same period of the previous year.

Compared with developed countries, China's gear manufacturing industry still has some problems, such as insufficient independent innovation capacity, slow development of new products, disordered market competition, weak enterprise management, low level of informatization, and the comprehensive quality of employees to be improved. At this stage, the gear industry should improve the industry concentration through market competition and integration to form a group of large, medium and small enterprises with assets of several billion yuan, 500 million yuan and 100 million yuan; Through the design and development of independent intellectual property products, a group of leading enterprises of vehicle transmission (gearbox, drive axle assembly) have been formed, and the ability and resources of the gear industry have been integrated with the supporting ability of the leading enterprises; Realize professional and networked supporting facilities, and form a large number of famous enterprises with distinctive processes, products and quick response capabilities; The transformation of modern gear manufacturing enterprises will be realized through technological transformation.

At the end of the 11th Five Year Plan period, the annual sales of China's gear manufacturing industry can reach 130 billion yuan, with the per capita sales rising to 650000 yuan/year, ranking the second in the world. From 2006 to 2010, 100,000 new equipment will be added, that is, about 6 billion yuan will be invested in new equipment every year, 20,000 new machine tools will be purchased, and the average unit price of each machine is 300,000 yuan. By 2010, China's gear manufacturing industry should have about 400000 machine tools of all kinds, including 100000 CNC machine tools, with a CNC rate of 25% (higher than the average value of the whole industry of machinery manufacturing by 17%).

Customers in any industry using forgings can request a quote for any number of forged products, from one prototype at a time and small batches to high volume production.