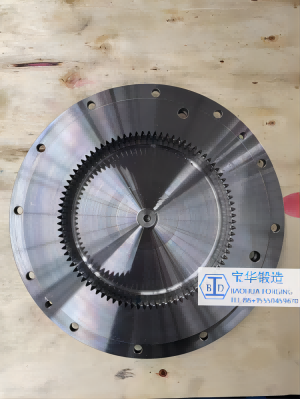

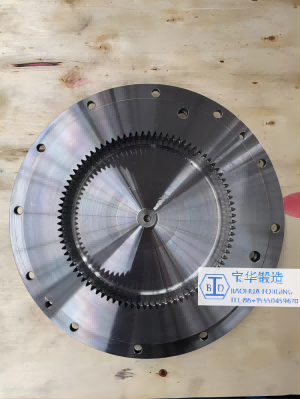

End CapFor Inner Ring Gear Products

The internal gear ring is produced through seamless rolling technique. in addition, the outstanding and excessive-strength wear of the inner equipment ring is found out through the float of fashioned grains, reduction of grain size and hot running, hence enhancing the mechanical homes and metallurgical balance of the open die forging procedure.

The internal equipment ring has bendy manufacturing form, low extent requirement and form close to the very last addition, in order that it can be produced on a big scale and store price.

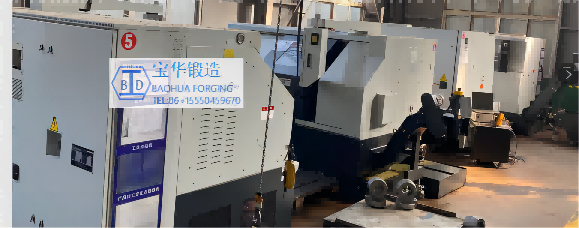

With regard to inner ring end cap, we can make many kinds of materials according to customer requirements, such as 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc. Our company independently develops ring forging process, which can greatly improve forging efficiency and reduce blanking weight, and ultimately achieve the purpose of cost saving. According to the weight, forging is carried out on different forging equipment units. The weight of forged products can reach 6kg-2000kg. The forging process needs to be completed by heating, pre-forging and forming. Our company can provide rough machined blanks or finished parts according to customer requirements.

Customers in any industry using inner ring end caps can request quotations for any number of forged inner ring end caps, ranging from one prototype at a time and a small batch to mass production.

Inquiries are welcome online or by mail.