Stud Tee Products

There are two kinds of screw-type tees in the manufacturing process: forging and casting. Forging refers to forging steel ingots or round bars by heating, and then turning them on a lathe to process threads. Casting refers to melting steel ingots, pouring them into tees, and cooling them. Because of the different manufacturing processes, the size of its pressure is also different, and the pressure resistance of forging is much higher than that of casting.

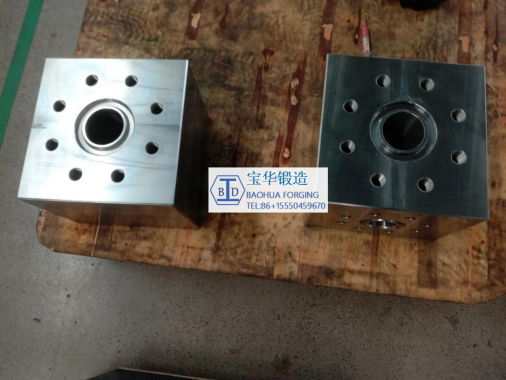

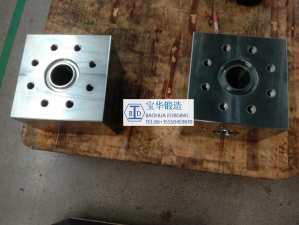

Our company's manufacturing process is mainly forging. Through a series of processes such as billet casting, rough cutting, fine turning, boring, drilling, heat treatment, quality inspection, etc., the screw-type tee produced has strong pressure resistance.

For the forging and casting of screw tee, our Baohua Company mainly focuses on forging. Customers can make requests according to their own needs, and we will carry out forging production according to the drawings provided. Like simple and numerous products, our company's mold engineers improve the production speed and accuracy of products by building molds.

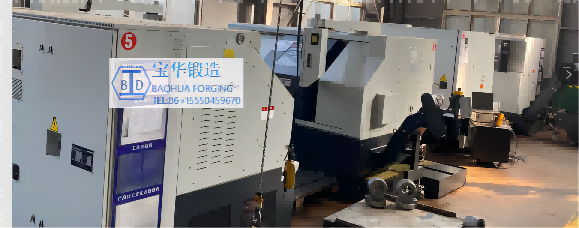

For our enterprise itself, from the state-owned to the individual, it has gone through three generations of family management, and the equipment is constantly updated. From the previous three or four sets to now more than 100 sets of mechanical equipment, the inspection equipment is also tested according to international standards, and it has also passed and been audited by foreign related industries such as ISO9001, API, SQ1, etc. The quality of products can be guaranteed, and problems can be solved online and offline in time.

Customers who have product requirements in related industries are welcome to consult online or by email.Manager Hou: 86+15550459670