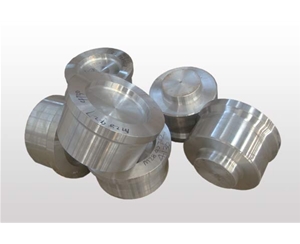

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-5000kg, Forging needs to be completed through heating, pre-forging, forming and other processes.

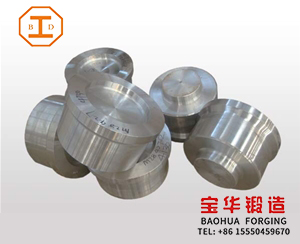

Stainless steel forgings refer to the articles in which stainless steel materials are pressed to shape the required shape or suitable compression force through plastic deformation.

This force is typically achieved by using a hammer or pressure. Forging can eliminate as cast porosity and other defects produced in the smelting process of metal, optimize the microstructure. At the same time, due to the preservation of complete metal streamline, the mechanical properties of forgings are generally superior to castings of the same material.

For important parts with high load and severe working conditions in related machinery, forgings are mostly used, except for simple rolled plates, profiles or weldments.

Stainless Steel Forgings

Forging can eliminate as cast porosity and other defects produced in the smelting process of metal, and optimize the microstructure. Because the metal streamline is preserved, the mechanical properties of forgings are generally superior to castings of the same material.

For important parts with high load and severe working conditions in machinery, forgings are mostly used, except for simple rolled plates, profiles or weldments.

Customers in any industry of forgings can request a quote for any number of connectors, from one prototype at a time and small batches to high volume production.