Sell High Neck Flange Finished Products

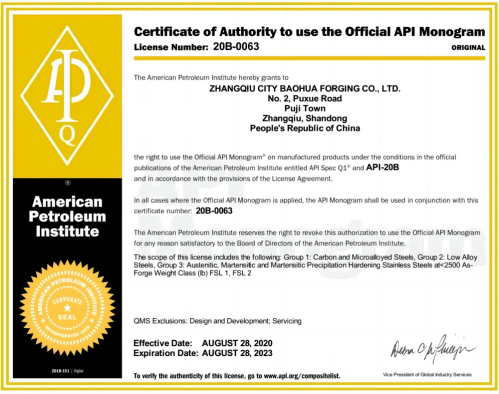

The production of high-neck flange has to go through a series of processing, such as casting blank, rough cutting, fine turning, boring, drilling, heat treatment, quality inspection, etc. We process the high-neck flange at different stages according to the requirements of customers. And there are certificates such as API recognized by american petroleum institute, and the quality can be guaranteed. The high-neck flanges we process and produce are mainly used in petroleum and construction machinery and equipment industries. The materials used in processing and production are flexible and can be forged according to the shape and size provided by customers.

Our advantage in flange production is that seamless ring rolling process is adopted, which can save cost and can be processed in batches.

In the production of high neck flange, the flange is formed by hot pressing or cold pressing, including the processing of screw holes and the opening of the flange.

During the inspection, the welded flange is inspected, such as pressure test, chemical composition analysis, magnetic particle inspection, etc., to ensure its quality meets the requirements.

Finally, in the surface treatment, the flange can be treated with zinc plating, spraying and electroplating to enhance its corrosion resistance and aesthetics.

Product Details:

| Material | 4130-75k |

| Hardness | 207-237 |

| Inner Diameter | 52.7 |

| Outside Diameter | 311 |

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad. The company has its own technology research and development organization "Zhangqiu Baohua Forging Technology Development Center".

The company's main management, technical personnel and key equipment operators have more than 15 years of working experience in the same industry, and the company has successively passed ISO9001, ISO14001 and APIQ1 since 2001, and obtained the "Special Equipment Manufacturing License".

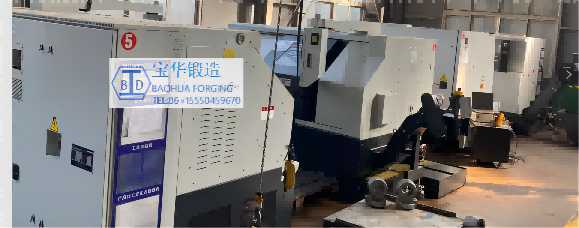

At present, our forging equipment in Baohua Company mainly includes: five tons and three tons of free forging hammers, 2500 tons, 1000 tons and 600 tons of friction presses, six large plywood hammers and various types of air hammers; There are more than 60 sets of machining equipment, including CA5116E*1015 vertical lathe, CW61100B and CW50 lathe. There are 2 sets of well-type and trolley-type electric furnaces for heat treatment. There are two tempering furnaces, which can complete product normalizing, annealing, tempering and other technological treatments. Equipped with a nationally recognized physical and chemical laboratory, the main testing equipment is a spectrometer imported from Germany with a value of nearly 500,000 yuan; Brinell hardness tester imported from the United States with a value of 120 thousand yuan can carry out ultrasonic nondestructive testing and mechanical performance test.

Our Baohua company carries out production and processing according to customer's requirements and drawings provided, eliminates welding repair and ensures product quality. For details, please contact us by email. zhangqiubaohua@126.com

Our Baohua company carries out production and processing according to customer's requirements and drawings provided, eliminates welding repair and ensures product quality. For details, please contact us by email. zhangqiubaohua@126.com

Related News

Submitted successfully

We will contact you as soon as possible