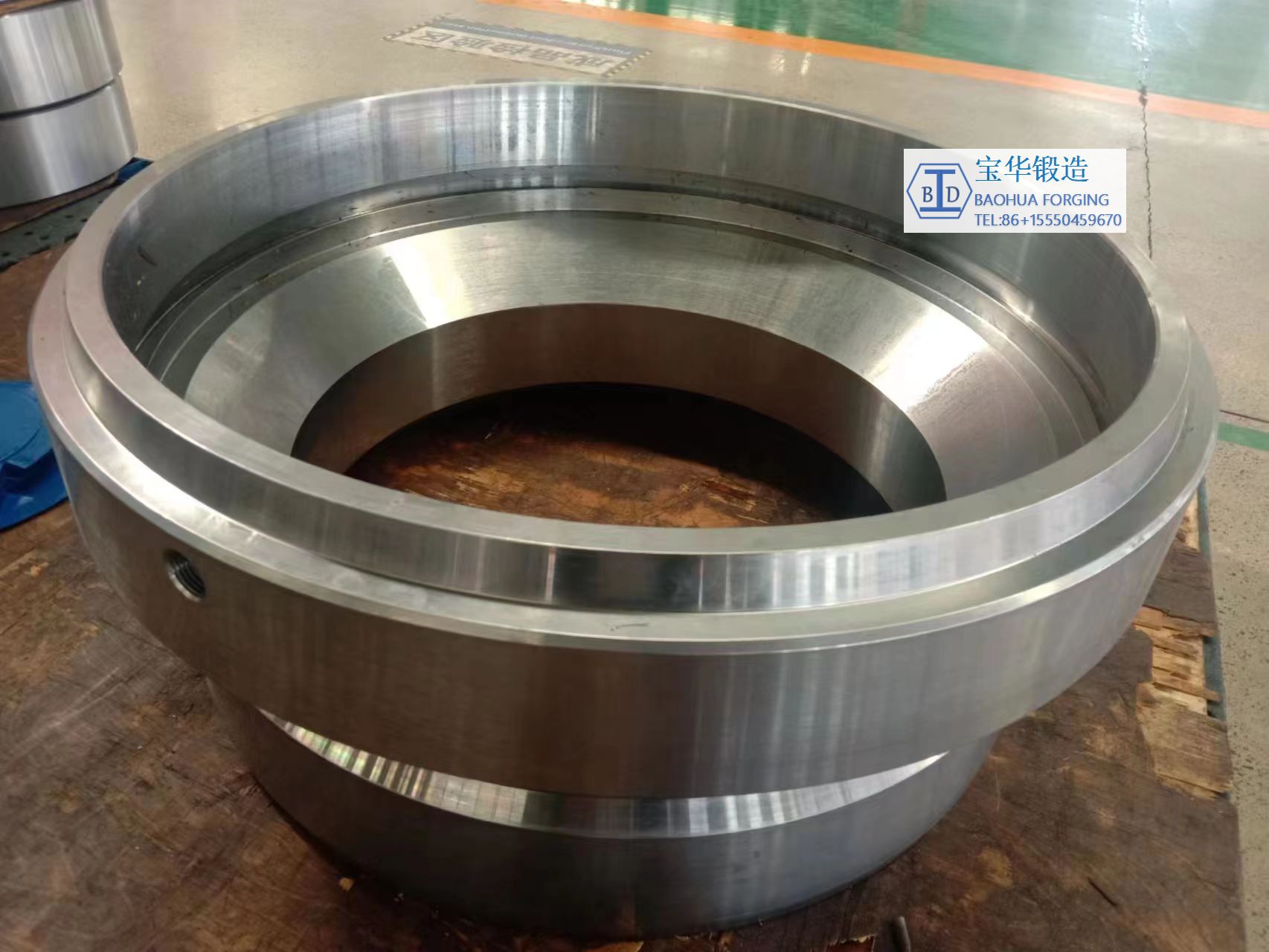

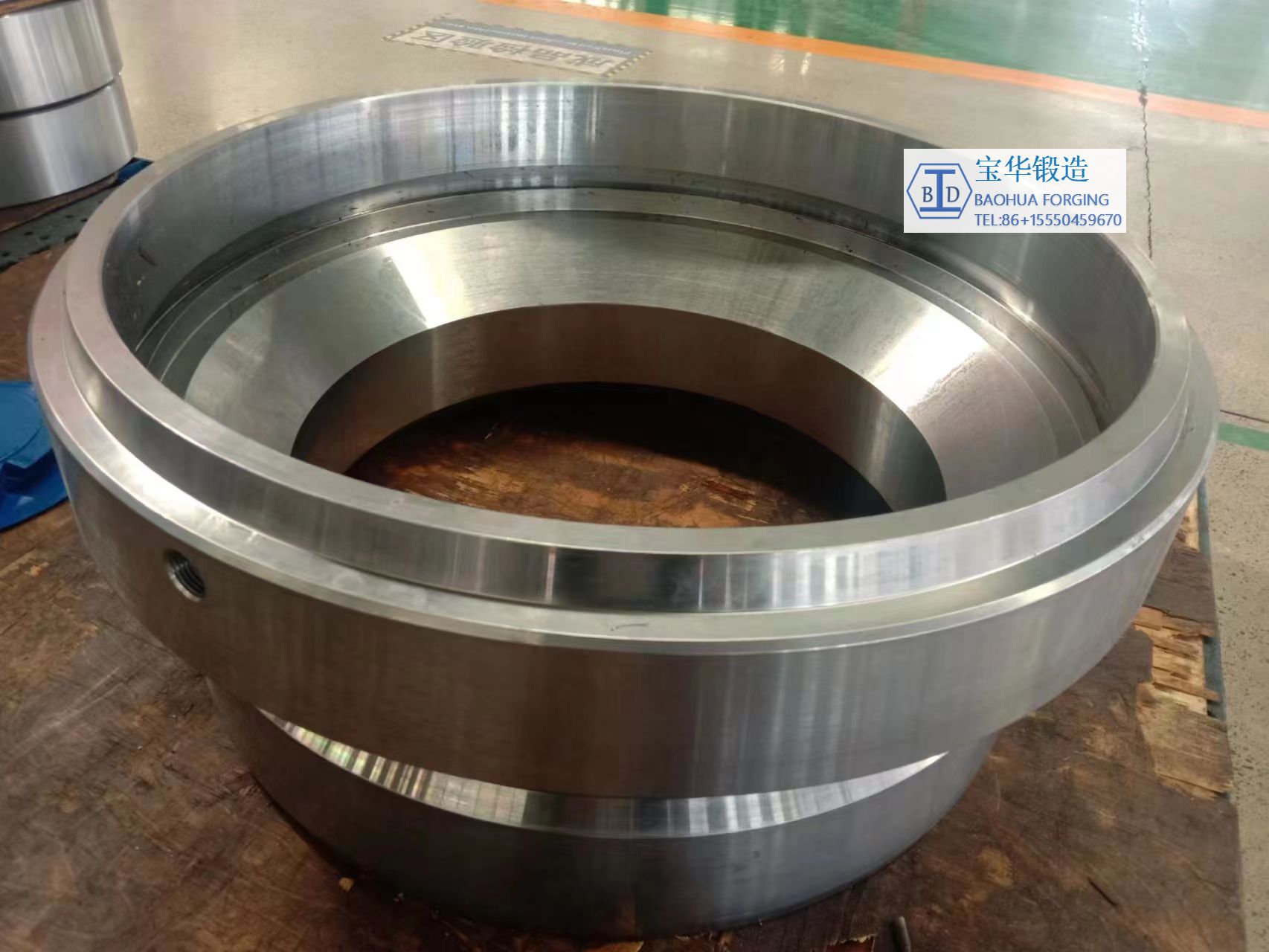

Sell Finished Flange Products

The production of flange should go through a series of processing, such as casting blank, rough cutting, fine turning, boring, drilling, heat treatment, quality inspection, etc. We process the flange in different stages according to the requirements of customers. And there are certificates such as API recognized by american petroleum institute, and the quality can be guaranteed. The flanges we process and produce are mainly used in petroleum and construction machinery and equipment industries. The materials used in processing and production are flexible and can be cast according to the shape and size provided by customers.

Our advantage in flange production is that seamless ring rolling process is adopted, which can save cost and can be processed in batches.

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges. Flange connection or flange joint refers to the detachable connection of flange, gasket and bolt as a set of combined sealing structure. Pipeline flange refers to the flange used for piping in pipeline device, and the inlet and outlet flange of equipment when it is used on equipment. There are holes in the flanges, and bolts make the two flanges closely connected.

The flange is sealed with a gasket. Flanges are threaded, welded and clamped. Flanges are used in pairs. Threaded flanges can be used for low-pressure pipelines, and welded flanges can be used for pressures above 4 kg.

Add a gasket between the two flanges and fasten it with bolts. The thickness of flanges with different pressures is different, and the bolts used are also different. When pumps and valves are connected to pipelines, the parts of these devices are also made into corresponding flange shapes, which is also called flange connection.

All connecting parts that are bolted around two planes and closed at the same time are generally called "flanges", such as the connection of ventilation pipes. Such parts can be called "flange parts". But this connection is only a part of the equipment, such as the connection between the flange and the water pump, so it is not good to call the water pump "flange part". Smaller ones, such as valves, can be called "flange parts".

The advantage of our oil forging flange production is that it can be forged according to the shape and size provided by customers, and the new technology of seamless rolling ring is adopted to realize batch processing and production.

Welcome to consult online.