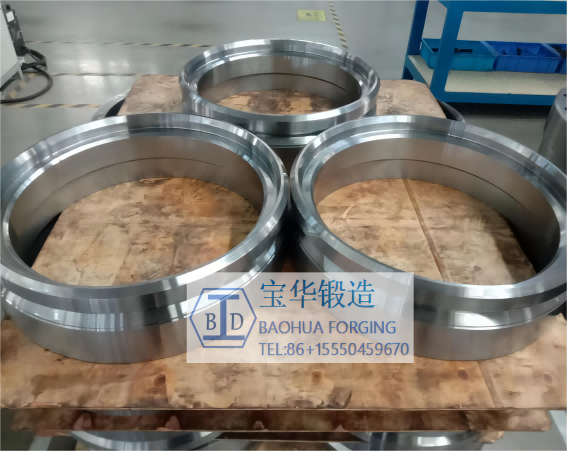

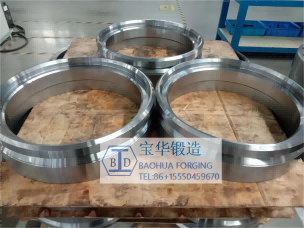

Ring Flange Products

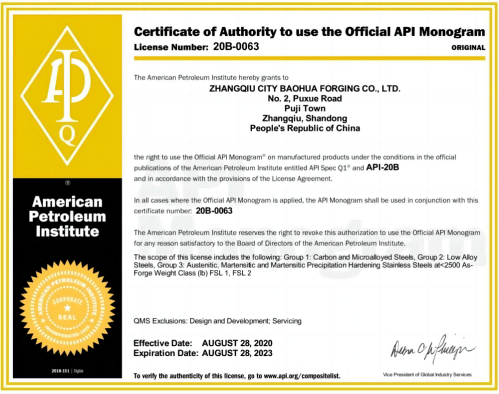

The flanges processed and produced by our Baohua Company are mainly used in petroleum and engineering machinery and equipment industries. The materials used in processing are flexible and can be cast according to the shape and size provided by customers.

Our advantage in the production of flanges is the seamless rolling process, which can save costs and can be processed in batches.

Our corporation makes use of the seamless rolling ring process, which makes the product more solid and can greatly reduce the weight of blanking and save fee. forged flanges may be made of a extensive range of materials inclusive of but not limited to 4140, 4130, 35crmo, 20crmnmo and may be solid and machined in a extensive variety of sizes and sizes starting from 200mm to 3000mm in diameter.

Flange dimensions and common precautions

In addition to the functional design of the flange, its size is the most likely factor to affect the flange selection when designing, maintaining and updating the piping system. The interface between flange and pipe and the gasket used must be considered to ensure the correct size. In addition, some common considerations are as follows:

• Outer diameter: the outer diameter refers to the distance between two opposite edges of the flange surface.

• Thickness: The thickness is measured from the outside of the rim.

• Bolt circle diameter: it refers to the distance between relative bolt holes measured from center to center.

• Pipe size: The pipe size refers to the size corresponding to the flange.

• Nominal diameter: The nominal diameter is the size of the inner diameter of the flange connector.

All of our forgings can be solid with the aid of warm-die forging, tough running, warmness treatment and other strategies, increasing the forging ratio and performance stability. flange forgings may be similarly processed to obtain very last assembly situations. welcome to order on-line.