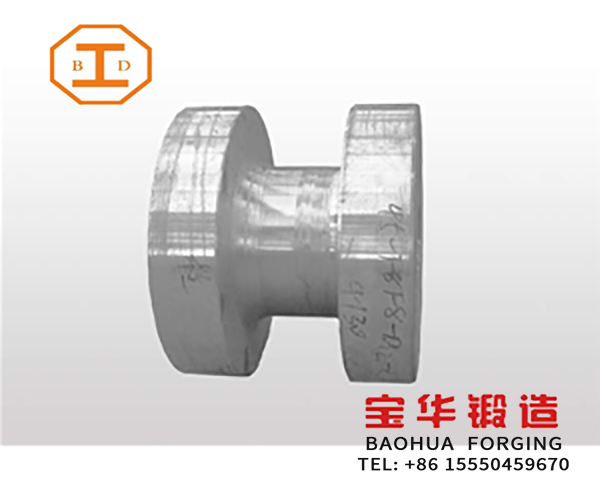

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-7000kg, forging needs to be completed through heating, pre-forging, forming and other processes. Our company can also finish finished product delivery.

Quality standard: manufactured in strict accordance with relevant national standards

Product specification: DN15-DN300

Product packaging: wooden case or others

Product color: metallic white

Product features: corrosion resistance, acid and alkali resistance, long service life, reasonable price calculation, smooth surface, acid and alkali resistance, high temperature resistance, reasonable price calculation, shape

Beautiful, strong texture performance

Production process: professional overall forging, forging manufacturing, etc

Processing method: high-precision CNC lathe turning, ordinary lathe fine turning, argon arc welding and other processing

Nominal pressure sch5s, sch10s, sch20s, sch30s, sch40s, etc

Manufacturing standards: national standard, American standard, Russian standard, Japanese standard, etc

Material: 304.316.316L.0Cr18Ni9.321.202, etc

Application: widely used in water conservancy, electric power, power station, pipe fittings, industry, pressure vessels, etc

Connection mode: flange nut, bolt connection, screw connection

Product process standard and quality control: feeding - physical and chemical - blanking - hot forging forming - heat treatment - inspection - metal processing - finished product inspection - identification - cost

Product inspection - identification - packaging and typing - shipment

Customers in any industry of Reducing Flanges can request a quote for any number of flanges, from one prototype at a time and small batches to high volume production.