High Neck Flange

Organisation blessings: adopting seamless ring rolling system can keep expenses and may be processed in batches.

The production of flange must go through a chain of processing, which includes casting blank, rough cutting, quality turning, boring, drilling, heat treatment, first-class inspection, etc. we procedure the flange in different ranges in line with the necessities of clients. and there are certificate along with api recognized via american petroleum institute, and the quality may be assured. the flanges we procedure and convey are particularly utilized in petroleum and creation equipment and gadget industries. the substances used in processing and manufacturing are flexible and may be forged in keeping with the form and length furnished with the aid of customers.

Flange, also known as flange or flange. flange is a part of connecting shaft, which is used to attach pipe ends; it is also used for flanges on the inlet and outlet of system, and is used for the connection among two equipment, along with decreasing pipe flanges. there are holes in the flanges, and bolts make the 2 flanges closely connected. all connecting elements that are bolted around two planes and closed at the identical time are normally called "flanges", consisting of the connection of air flow pipes. such parts can be known as "flange elements". but this connection is only a part of the device, together with the connection between the flange and the water pump, so it is not suitable to call the water pump "flange element". smaller ones, along with valves, can be known as "flange components".

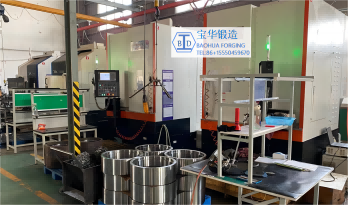

Our baohua company become based in 1969, and it has long past thru 3 generations from kingdom-owned to character operation, overlaying a place of a hundred and forty,000 ㎡, with 260 employees, 46 engineering technicians and greater than a hundred finishing operation device.

The agency's forging equipment particularly includes: five lots and three heaps of loose forging hammers, 2500 tons, a thousand lots and six hundred heaps of friction presses, six big splint hammers and diverse forms of air hammers; there are more than 60 sets of machining device, including ca5116e*1015 vertical lathe, cw61100b and cw50 lathe. there are 2 sets of nicely-kind and trolley-type electric powered furnaces for warmth treatment. there are two tempering furnaces, that could whole product normalizing, annealing, tempering and other technological remedies. ready with a nationally recognized bodily and chemical laboratory, the primary testing equipment is a spectrometer imported from germany with a cost of nearly 500,000 yuan; brinell hardness tester imported from the us with a cost of 120 thousand yuan can carry out ultrasonic nondestructive testing and mechanical performance test.

Inside the manufacturing of high neck flange merchandise, our baohua organization has to go through a sequence of techniques consisting of casting blank, rough cutting, satisfactory turning, boring, drilling, heat remedy and fine inspection. and has the iso9001 satisfactory certificate, the exceptional may be guaranteed. the flanges we manner and bring are mainly used in petroleum and creation machinery and equipment industries. the substances utilized in processing and manufacturing are flexible and can be solid in step with the shape and length provided by clients.

Welcome to online consultation.