Flange On The Oil Forgings

Our advantage in flange production is that seamless ring rolling process is adopted, which can save cost and can be processed in batches.

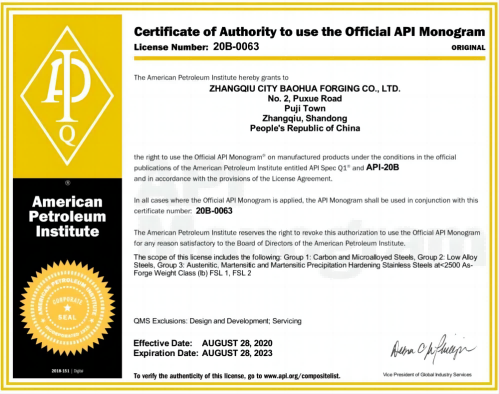

The production of flange should go through a series of processing, such as casting blank, rough cutting, fine turning, boring, drilling, heat treatment, quality inspection, etc. We process the flange in different stages according to the requirements of customers. And there are certificates such as API recognized by american petroleum institute, and the quality can be guaranteed. The flanges we process and produce are mainly used in petroleum and construction machinery and equipment industries. The materials used in processing and production are flexible and can be cast according to the shape and size provided by customers.

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges. There are holes in the flanges, and bolts make the two flanges closely connected. All connecting parts that are bolted around two planes and closed at the same time are generally called "flanges", such as the connection of ventilation pipes. Such parts can be called "flange parts". But this connection is only a part of the equipment, such as the connection between the flange and the water pump, so it is not appropriate to call the water pump "flange part". Smaller ones, such as valves, can be called "flange parts".

Our Baohua Company was founded in 1969, and it has gone through three generations from state-owned to individual operation, covering an area of 140,000 ㎡, with 260 employees, 46 engineering technicians and more than 100 finishing operation equipment.

The company's forging equipment mainly includes: five tons and three tons of free forging hammers, 2500 tons, 1000 tons and 600 tons of friction presses, six large splint hammers and various types of air hammers; There are more than 60 sets of machining equipment, including CA5116E*1015 vertical lathe, CW61100B and CW50 lathe. There are 2 sets of well-type and trolley-type electric furnaces for heat treatment. There are two tempering furnaces, which can complete product normalizing, annealing, tempering and other technological treatments. Equipped with a nationally recognized physical and chemical laboratory, the main testing equipment is a spectrometer imported from Germany with a value of nearly 500,000 yuan; Brinell hardness tester imported from the United States with a value of 120 thousand yuan can carry out ultrasonic nondestructive testing and mechanical performance test.

In the production of high neck flange products, our Baohua company has to go through a series of processes such as casting blank, rough cutting, fine turning, boring, drilling, heat treatment and quality inspection. And has the ISO9001 quality certificate, the quality can be guaranteed. The flanges we process and produce are mainly used in petroleum and construction machinery and equipment industries. The materials used in processing and production are flexible and can be cast according to the shape and size provided by customers.

Customers with product requirements in related industries are welcome to consult online or by email.