Blind Flange Products

Blind flange is a kind of flange connector that can't pass through holes or valves. Advantages of blind flange:

1. Safe and reliable: the blind flange can completely seal the pipeline to prevent leakage and pressure out of control.

2. Convenient use: the blind flange does not need to be disassembled, so it can be inspected and maintained conveniently.

3. Corrosion resistance: Blind flanges are usually made of highly corrosion-resistant materials and can be used for a long time in harsh environments.

4. Wide application: The blind flange can be used for various fluids, including water, oil and chemicals.

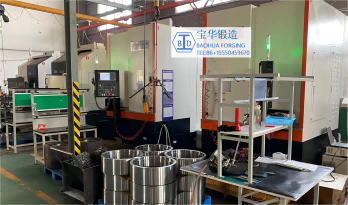

Our advantages: we can independently design molds according to drawings, realize mass production, and have high efficiency and economy.

Blind flanges are used to connect valves, pipes, pumps and other equipment in industrial pipelines. It is widely used in chemical industry, petroleum, natural gas, food, pharmacy, electric power and other industries. There are many kinds of flanges, which can be divided into flange connection, threaded connection and clamp connection according to the connection mode. According to the material and anti-corrosion method, it can be divided into single material flange, plastic-coated flange inside and outside, galvanized flange inside and outside, etc. Choosing the appropriate flange type and material can effectively ensure the safe, stable and efficient operation of the pipeline.

In the production process, the blind flange mainly goes through the processing technology of material selection, stamping, forming, welding, testing and surface treatment.

In terms of material selection, according to the requirements of flange's use environment, working pressure and temperature, the appropriate material is selected for production. Generally, carbon steel, stainless steel, cast iron, alloy steel, copper and other materials can be selected.

In stamping, the material is cut into the required size and shape by the die.

In molding, the flange is molded by hot pressing or cold pressing, including the processing of screw holes and the opening of the flange.

In welding, the formed flange is welded to improve its strength and durability.

During the inspection, the welded flange is inspected, such as pressure test, chemical composition analysis, magnetic particle inspection, etc., to ensure its quality meets the requirements.

Finally, in the surface treatment, the flange can be treated with zinc plating, spraying and electroplating to enhance its corrosion resistance and aesthetics.

Our Baohua Company conducts production and processing according to customer's requirements and drawings provided, eliminates welding repair and ensures product quality. For details, please call or communicate online.