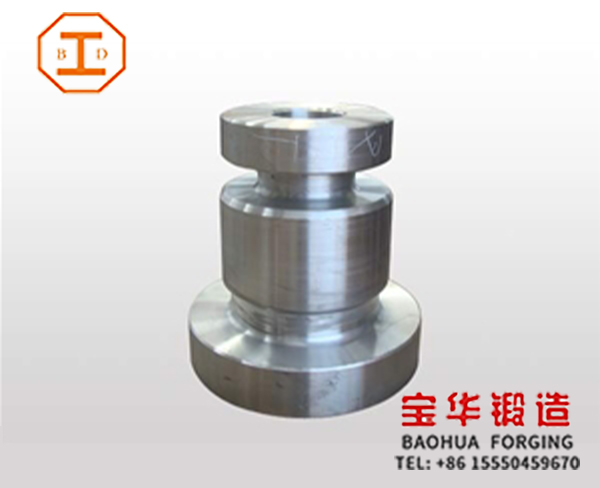

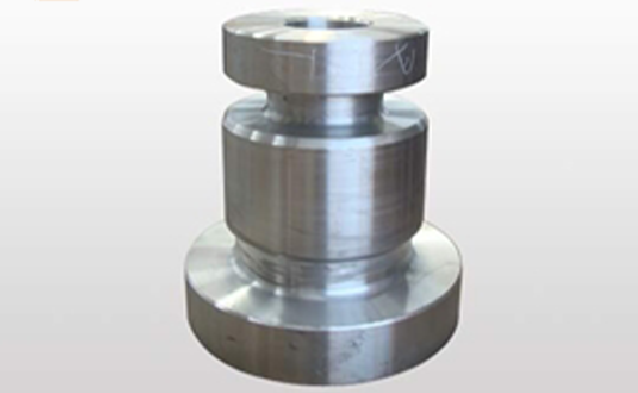

4 Way Cross Forged Pipe Fitting

One-piece forging molding

Forging is a processing method that uses forging machinery to exert pressure on metal blank to make it produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Forging (forging and stamping) is one of the two major components.

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units, and the weight of the forged products can reach 6kg-5000kg, forging needs to be completed through heating, pre-forging, forming and other processes.

Forging is a processing method that uses forging machinery to exert pressure on metal blank to make it produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Forging (forging and stamping) is one of the two major components. Forging can eliminate as cast porosity and other defects produced in the smelting process of metal, optimize the microstructure. At the same time, due to the preservation of complete metal streamline, the mechanical properties of forgings are generally superior to castings of the same material. For important parts with high load and severe working conditions in related machinery, forgings are mostly used, except for simple rolled plates, profiles or weldments.

The die movement and degree of freedom of the forging equipment are inconsistent. According to the deformation limitation characteristics of the lower dead center, the forging equipment can be divided into the following four forms:

1. Form of limited forging force: hydraulic press that directly drives the sliding block by oil pressure.

2. Quasi stroke limit mode: oil press that drives crank linkage.

3. Stroke limit mode: mechanical press with slider driven by crank, connecting rod and wedge mechanism.

4. Energy limiting mode: screw and friction press with screw mechanism.

In order to obtain high accuracy, attention should be paid to preventing overload at the bottom dead center, and controlling the speed and mold position. Because these will affect the forging tolerance, shape accuracy and die life. In addition, in order to maintain the accuracy, attention should also be paid to adjusting the slider guide clearance, ensuring the rigidity, adjusting the lower dead center and using auxiliary transmission devices and other measures.

Customers in any industry of forgings can request a quote for any number of forgings, from one prototype at a time and small batches to high volume production.