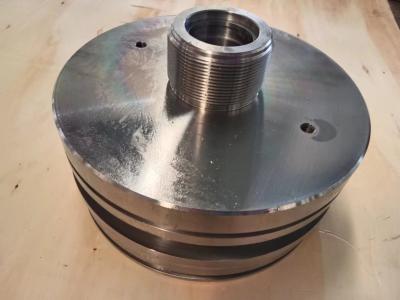

Rotor Products

For the production of Rotor, we are able to independently design the molds and form them in one piece according to the drawings provided by customers, so as to achieve mass production and improve production efficiency.

Our company is able to design the die according to the drawing according to the customer's requirements and achieve precision die forging, so that the utilization rate of rough rotor materials can reach more than 90%, which greatly saves costs. Our company can deliver according to the needs of customers with different delivery status. The quantity can also be purchased from one to more.

Welcome customers to consult online.

According to ISO standards, a rotating body supported by bearings is called a rotor. Rotor is the main rotating part of power machinery and working machinery.

The rotating part of an electric motor or some rotating machinery, such as a turbine. The rotor of the motor is generally composed of an iron core, a slip ring, a fan blade, etc. wound with a coil. [1]

Motor, generator, gas turbine, turbine compressor and other main components of power machinery or working machinery rotating at high speed.

Rotor products

The main rotor rotates at high speed, and when its speed is close to the critical speed, the shaft will produce deflection deformation. Even mechanical damage caused by resonance. The natural frequency of the transverse vibration of the rotor is multi order, so its corresponding critical speed is also multi order. When the working speed of the rotor is lower than the first critical speed, it is called a rigid rotor, while when the working speed of the rotor is higher than the first critical speed, it is called a flexible rotor.

The operating speed of any type of rotor shall not be close to the critical speed. The critical speed of a rotor depends on its manufacturing materials, structural forms, geometric dimensions, support characteristics and other factors.