Gear is a commonly used mechanical transmission element, which is used to transmit torque and rotary motion. It is composed of one or more tooth top parts, with tooth grooves or teeth marks, and the transmission of force and motion between gears is realized by meshing. Attached product information:MATERIAL18CrNiM07-6HARDNESS140-240INNER DIAMETER210OUTSIDE DIAMETER610Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians.

Contact Now

The cylinder head in engineering usually refers to the cylinder head of the engine. Engine is the core power device of all kinds of construction machinery, and cylinder head is an important part of engine.Hydraulic cylinder is a common executive component in construction machinery, which is used to produce linear motion or drive other equipment.

Contact Now

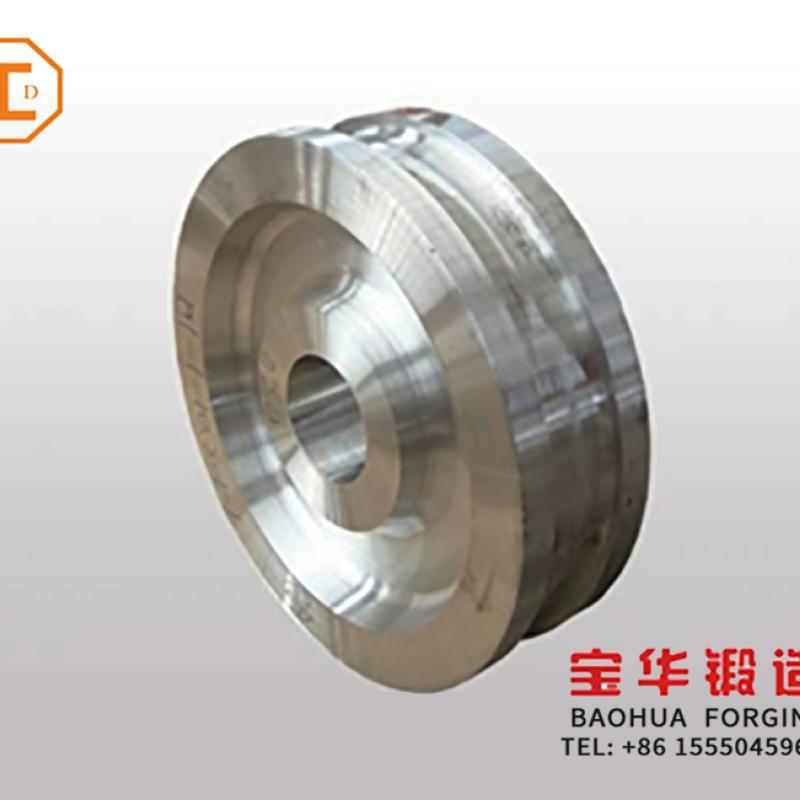

Forging gear and ring gear blank processBAOHUA makes use of a unbroken rolled ring method to offer cast tools producers with shape, length and material flexibility, decrease volume necessities and near-completed shapes to store on very last machining costs. Higher nice and accelerated electricity and put on in cast tools blanks is done from contoured grain flow, decreased grain length and thermal processing that improves mechanical residences and metallurgical soundness from the open die forging manner.

Contact Now

Gear is a common mechanical transmission device, which consists of one or more gears. The finished gear is mainly made of 18CrNiMo7-6. After turning, milling, drilling, planing, rolling, shaving, grinding and heat treatment. Further finish machining from primary machining. Details of this product are as follows:Product NameGear FinishedMaterial18CrNiMo7-6HARDNESS140-240INNER DIAMETER210OUTSIDE DIAMETER611Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Contact Now

Gear is a common mechanical transmission device, which consists of one or more gears. Product details are as follows:NAMEGEARMATERIAL18CrNiMo 7-6HARDNESS140-240INNER DIAMETER121OUTSIDE DIAMETER299.48Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Contact Now

The internal gear ring is a kind of ring-shaped part with internal tooth structure, which is usually used in reducers and hydraulic machinery in mechanical transmission systems. The input speed and torque can be reduced and increased at the output end through the gear transmission of the internal gear ring.Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing.

Contact Now

Gear is a commonly used mechanical transmission element, which is used to transmit torque and rotary motion. It consists of one or more tooth tips, usually in the shape of a disk or a cylinder. The main function of gear is to realize the transmission of speed and torque, and at the same time, it can also change the steering and transmission direction.NAMEGEARMATERIAL18CrNiM07-6HARDNESS140-240INNER DIAMETER121OUTSIDE DIAMETER299.48Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Contact Now

The gear ring produced by using our baohua business enterprise is particularly used within the equipment elements of creation machinery. forging the scale of the inner gear ring consistent with the requirements of clients for the usage of spherical steel in product substances.

Contact Now

The internal gear ring is a kind of circular gear, the teeth of which are inward. It is usually used to transmit mechanical systems such as differential, reducer, steering gear, planetary gear box, etc.

Contact Now

Our company independently designs dies and forges according to product specifications. Material types and weights can be made according to customer requirements. This gear company independently designed the die to achieve precision forging, so that the material utilization rate reaches more than 90%, which greatly saves the cost. Our company also has roughing, heat treatment and finishing, which can be delivered according to customer requirements in different delivery states.

Contact Now

Casing hanger can be divided into slip type and mandrel type. Casing hanger in oil plays an important role in fixing, supporting, sharing pressure and preventing wellbore instability, which helps to ensure the safety, stability and integrity of oil wells.MATERIAL4140-130KHARDNESS301-341INNER DIAMETER146.04OUTSIDE DIAMETER275.55Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Contact Now

The internal gear ring produced by our Baohua Company is mainly used in the oil industry and equipment accessories of construction machinery. Forging the size of the internal gear ring according to the requirements of customers for using round steel in product materials.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. And has ISO 9001, API 20b and API Q1 certificates.The forging equipment of our Baohua company mainly includes: five tons and three tons of free forging hammers, 2500 tons, 1000 tons and 600 tons of friction presses, six large splint hammers and various types of air hammers, and 1000 tons of multi-directional die forging presses.

Contact Now

The higher quality and higher strength and wear of this product's forged gear bracelet is achieved through shaped grain flow, reduced grain size and thermal processing. Thereby, the mechanical properties and metallurgical stability of the open-die forging process are improved. All of our forgings can go through hot die forging, roughing, heat treatment, etc.

Contact Now

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges. Details are as follows:NAMEFlange In Oil FieldMATERIAL4130-75KHARDNESS207-237INNER DIAMETER387.35OUTSIDE DIAMETER509.52Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians.

Contact Now

BAOHUA produces solid gear, ring gear shapes for single, double and different close to internet shapes for completing into numerous unique shapes.OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsThese forged gear shapes may be crafted from ferrous and non-ferrous metals which include carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and device steel.Forging gear and ring gear blank processBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower

Contact Now

BAOHUA produces forged gear, ring gear shapes for single, double and other near net shapes for finishing into several different shapes. OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsThese forged gear shapes can be made from ferrous and non-ferrous metals including carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and tool steel.Forging gear and ring gear blank processBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requir

Contact Now

The internal gears produced by our Baohua Company are mainly used in the equipment accessories of petroleum industry and construction machinery. Forging the internal gear size according to the customer's requirement of using round steel in product materials.

Contact Now

Oil union, also known as pipe union. The oil union products produced by our company are sleeve type and flared type. Mainly used in automation equipment in petroleum machinery industry.At present, our Baohua company sells hundreds of products in China and indirectly exports them abroad. After years of processing experience, we can skillfully perform repeated pre-forging, heating die forging and other finishing processes for the processing and production of oil union. So that the forging of the oil union has good forging ratio and good durability.

Contact Now

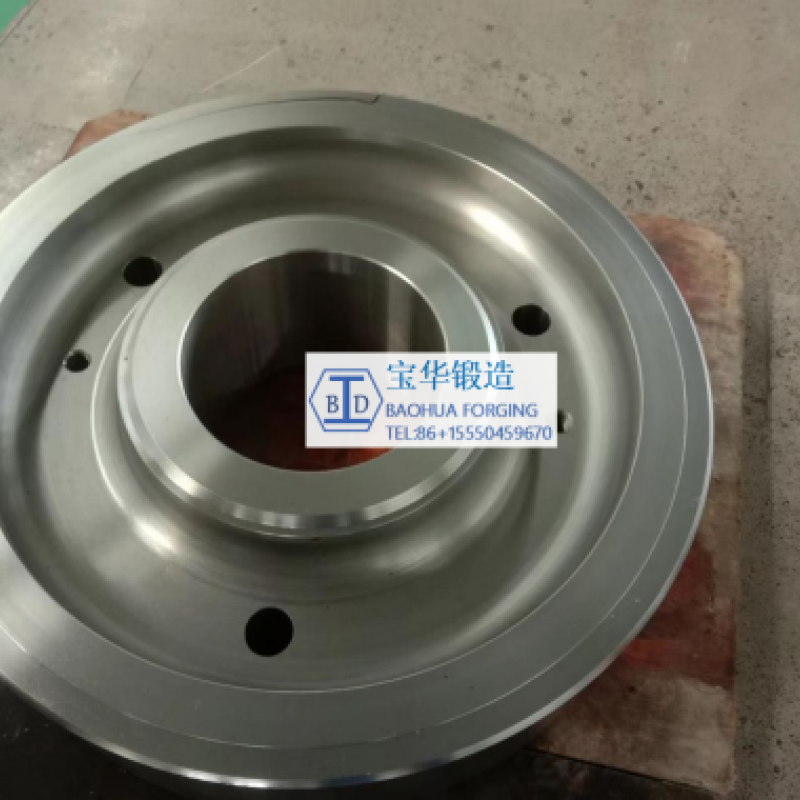

The purpose of the utility model is to overcome the above shortcomings of the prior art, propose a tooling for gear end caps, which can realize the positioning and fixation of various types of gear end caps.In order to achieve the above purposes, the utility model adopts the following technical solutions:The utility model relates to a tool for a gear end cover, which comprises a support plate for supporting the gear end cover; The gear end cover comprises a circular main body, a plurality of positioning holes on the main body, and a plurality of bolt holes on the main body; The positioning hol

Contact Now

Baohua company was established in 1969, from the initial rough machining to further finishing production. From three sets of processing equipment to more than 80 sets of processing equipment and inspection equipment, all of them are based on the production concept of honesty and customer-oriented.In general, the materials used in the production of gear rings are made of 45 or 40Cr steel.

Contact Now

The gear ring produced by our Baohua company is mainly used in the equipment parts of construction machinery. Forging the size of the internal gear ring according to the requirements of customers for using round steel in product materials.

Contact Now

Our manufactured output gear shaft can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials according to customer requirements. Forging can be carried out on different forging equipment units according to different weights. The forged product can weigh up to 6kg-500kg. The forging process needs to be completed by heating, pre-forging, forming and trimming. All these processes are integrated by our Baohua Company, thus ensuring the quality of products.In the design, the application of gear shaft generally involves the following situations:1.

Contact Now