Our company is able to design the die according to the drawing according to the customer's requirements and achieve precision die forging, so that the utilization rate of rough rotor materials can reach more than 90%, which greatly saves costs. Our company can deliver according to the needs of customers with different delivery status. The quantity can also be purchased from one to more.Welcome customers to consult online.According to ISO standards, a rotating body supported by bearings is called a rotor.

Contact Now

The torque arm on wind power refers to the part between the main shaft of the wind turbine and the rotor of the generator, which converts the torque transmitted by the rotating main shaft into the power that the generator drives the rotor to rotate, thus generating electric energy.The torque arm produced by our company is mainly used as accessories for wind power generation equipment. Raw materials are purchased from round steel with recognized quality at home and abroad.

Contact Now

Torque arm in wind power refers to an important structural part of wind turbine, which is used to convert wind energy into electric energy. The rotor of wind turbine usually includes impeller (blade), shaft and torque arm.

Contact Now

There are no special requirements for the material of the supporting shaft. In the process of production, manufacturers mainly produce according to their actual availability. Basically follow the following principles:1. Select the materials for manufacturing the supporting shaft according to the use of the main parts. If it is used for support, it should be made of materials that can bear the support. If it is used for fixing, it is necessary to select materials that are convenient for welding the support shaft and the fixing point.2.

Contact Now

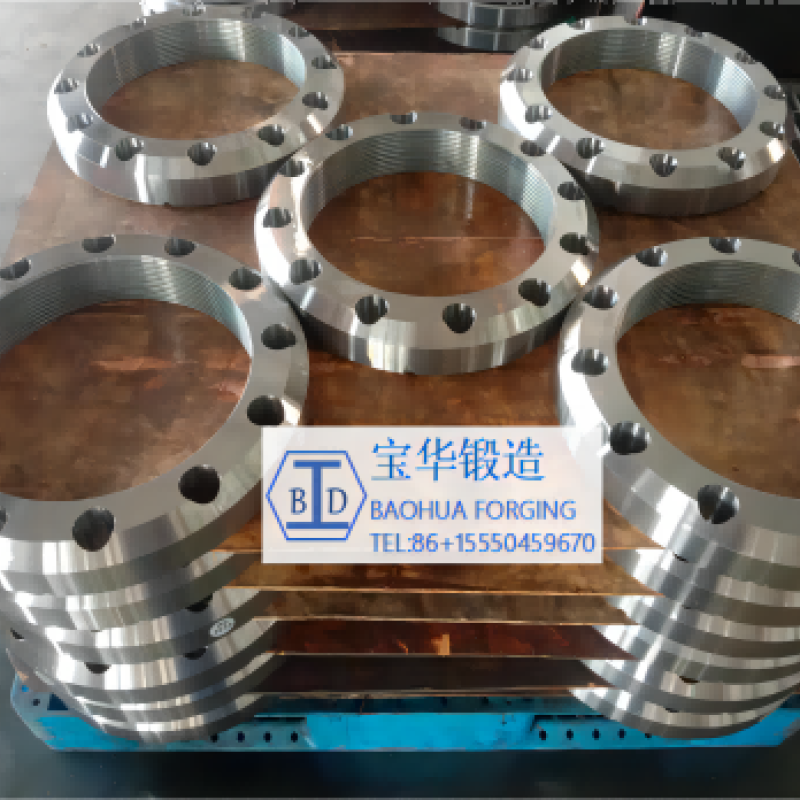

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment and for the connection between two equipment. There are holes in the flanges, and bolts make the two flanges closely connected.MATERIAL4130-75KHARDNESS207-237INNER DIAMETER635OUTSIDE DIAMETER812.8Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians.

Contact Now

These hollow shaft may be crafted from ferrous and non-ferrous metals which include carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and device steelBAOHUA produces solid gear, ring gear shapes for single, double and different close to internet shapes for completing into numerous unique shapes.OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requirements and near-finished shapes t

Contact Now

Our company has ISO9001, API, SQ1 and other certificates, more than 80 sets of processing machinery and equipment, as well as ZEISS CMM, Japanese small plate profiler, gear detector, Ω MEGA tool setting instrument and other inspection and testing equipment.For the production of tubing hanger products, our company can independently design the mold according to the drawings provided by the customer, and use different materials according to the product specifications, through a series of processes such as rough machining, heat treatment, and finishing for mass production.

Contact Now

With regard to inner ring end cap, we can make many kinds of materials according to customer requirements, such as 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc. Our company independently develops ring forging process, which can greatly improve forging efficiency and reduce blanking weight, and ultimately achieve the purpose of cost saving. According to the weight, forging is carried out on different forging equipment units. The weight of forged products can reach 6kg-2000kg. The forging process needs to be completed by heating, pre-forging and forming.

Contact Now

For the production of bearing seat products, our company can make many kinds of materials, such as 45, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 according to customer requirements. In addition, our company independently develops the forging process of two-die cavity, which can greatly reduce the weight of blanking and thus greatly improve the forging efficiency. In addition, forging can be carried out on different forging equipment units according to different weights. The forged product can reach 6 kg-500 kg.

Contact Now

Our company can independently design and process forging dies according to the drawings, and will try our best to save forging materials. The weight of the forged product can reach 6kg-500kg, and the forging needs to be completed through heating, pre-forging, forming, trimming and other processes.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg. Heating, pre-forging, forming, trimming and other processes are completed.Coupling refers to a device that connects two shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions.

Contact Now

The internal gear ring produced by our Baohua Company is mainly used in the equipment accessories of petroleum industry and construction machinery. Forging the size of the internal gear ring according to the requirements of customers for using round steel in product materials. Batch purchase can open molds for specialized supply and finishing production.Flanges can be made of a variety of materials including but not limited to 4140, 4130, 35CrMo, 20CrMnMO, and can be forged and machined with a diameter of 200mm to 3000mm.

Contact Now

The company adopts seamless rolling ring technology, which makes the product performance more stable, weight greatly reduced and cost greatly reduced. Forged threaded flanges can be made of a variety of materials, including but not limited to 4140, 4130, 35CrMo, 20CrMnMO, and can be forged and processed into various sizes and diameters ranging from 200mm to 3000mm. Customers in any industry using threaded flanges can request quotations for any number of forged threaded flanges, from one prototype at a time, small batch to mass production.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-7000kg, forging needs to be completed through heating, pre-forging, forming and other processes.

Contact Now

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

Contact Now

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

Contact Now

Our company uses the seamless rolling ring process, which makes the product more stable and can greatly reduce the weight of blanking and save cost. Forged flanges can be made of a wide range of materials including but not limited to 4140, 4130, 35CrMo, 20CrMnMO and can be forged and machined in a wide range of sizes and sizes ranging from 200mm to 3000mm in diameter.All of our forgings can be forged by hot-die forging, rough working, heat treatment and other processes, increasing the forging ratio and performance stability.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, and other processes.The die movement and degree of freedom of the forging equipment are inconsistent. According to the deformation limitation characteristics of the lower dead center, the forging equipment can be divided into the following four forms:1.

Contact Now

Connectors refer to components used to connect electrical components or electronic devices, which are an indispensable part of electronic circuits.Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Contact Now

The rod eye is usually a circular hole, and the rod eye on the hydraulic machinery refers to a connection point or hole on the hydraulic cylinder, which is used to connect other mechanical parts or transmit power. The rod eye of the hydraulic cylinder is usually located on the piston rod of the cylinder body, and can provide stable support and connection point.NAMEROD EYEMATERIALQ345BMHARDNESS140-180INNER DIAMETER85.03OUTSIDE DIAMETER155.2Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Contact Now

Baohua employer has the ability of independently designing molds, and may forge according to unique product specifications. substances and weights may be made in step with distinctive consumer necessities.

Contact Now

Baohua employer has the talent of independently designing molds, and may forge consistent with special product specifications. substances and weights may be made consistent with exclusive customer requirements.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now