The working medium used by the hydraulic press not only transfers the pressure, but also ensures that the working parts of the machine work sensitively, reliably, with long service life and less leakage. The basic requirements for working medium of hydraulic press are: ① proper fluidity and low compressibility to improve transmission efficiency; ② Able to prevent corrosion; ③ Good lubrication performance; ④ Easy to seal; ⑤ Stable performance, no deterioration after long-term operation.

Contact Now

Our baohua employer became founded in 1969. after three generations' hard paintings, it now covers an area of 50,000 ㎡ and has a constructing location of 25,000 ㎡. there are 260 personnel and 46 engineering technicians. the once a year output of forgings is 30,000 heaps. mainly in the car, hydraulic equipment, wind strength era, petroleum machinery parts, creation equipment, mining, metallurgy, shipbuilding machinery and other industries to supply related accessories. the goods bought are oriented at domestic and abroad.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-5000kg, Forging needs to be completed through heating, pre-forging, forming and other processes.Stainless steel forgings refer to the articles in which stainless steel materials are pressed to shape the required shape or suitable compression force through plastic deformation.This force is typically achieved by using a hammer or pressure.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons. Mainly in the automobile, hydraulic machinery, wind power generation, petroleum machinery parts, construction machinery, mining, metallurgy, shipbuilding machinery and other industries to produce related accessories. The products sold are oriented at home and abroad.

Contact Now

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges. There are holes in the flanges, and bolts make the two flanges closely connected. All connecting parts that are bolted around two planes and closed at the same time are generally called "flanges", such as the connection of ventilation pipes. Such parts can be called "flange parts".

Contact Now

Our BaoHua business enterprise is a nation-owned agency, which has a history of more than 60 years. from the preliminary forging of iron parts to the existing roughing, warmth treatment and finishing of forgings. devices and device additionally observe the contemporary product manufacturing requirements. at present, there are more than 80 units of processing equipment, together with zeiss 3-coordinate, eastern small plate contour meter, equipment tester, omega device counter and other inspection and trying out device. the company has handed iso9001, api, sq.

Contact Now

Our Baohua Company is a state-owned to private enterprise. The family business has a history of more than 60 years, from the initial forging iron pieces to the current rough processing, heat treatment and finishing of forgings. Instruments and equipment also closely follow the requirements of modern product production. At present, there are more than 80 processing equipment, as well as ZEISS CMM, Japanese small board profiler, gear detector, Ω MEGA tool setting instrument and other inspection and detection equipment.

Contact Now

Our Baohua Company is a state-owned enterprise, which has a history of more than 60 years. From the initial forging of iron parts to the present roughing, heat treatment and finishing of forgings. Instruments and equipment also follow the current product production requirements. At present, there are more than 80 sets of processing equipment, including ZEISS three-coordinate, Japanese small plate contour meter, gear tester, Omega tool counter and other inspection and testing equipment.

Contact Now

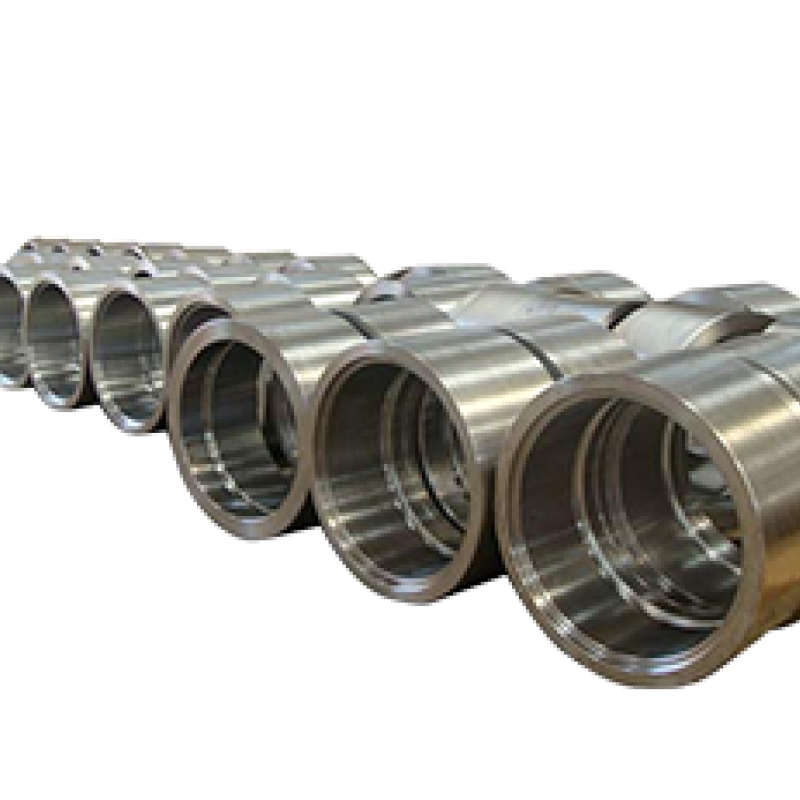

This product can be repeatedly forged after heating, and can also be modulated and heat treated and finished according to customer requirements. After repeated forging, the forging ratio is high and the durability is good. It is suitable for key parts of equipment. For casing heads, our company can forge 10kg-5000kg forgings, and can forge a variety of materials including 42CrMo, 4140, 4130, 40Cr, 20CrMnMo, 18CrNiMo7-6, 410SS.

Contact Now

Connectors refer to components used to connect electrical components or electronic devices, which are an indispensable part of electronic circuits.Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units, and the weight of the forged products can reach 6kg-5000kg, forging needs to be completed through heating, pre-forging, forming and other processes.Forging is a processing method that uses forging machinery to exert pressure on metal blank to make it produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes.

Contact Now

A device used to plug a specific well layer or reservoir in a casing, which can prevent the flow of fluid by expansion or differential pressure sealing.Material45#Hardness241-287Inner Diameter50.8Outside Diameter223.5Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Contact Now

This product may be time and again solid after heating, and also can be modulated and heat handled and finished according to purchaser necessities. after repeated forging, the forging ratio is excessive and the durability is good. it's miles suitable for key elements of gadget. for casing heads, our employer can forge 10kg-5000kg forgings, and can forge an expansion of materials along with 42CrMo, 4140, 4130, 40Cr, 20CrMnMo, 18CrNiMo7-6, 410ss.

Contact Now

Our company employs a new seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requirements and near-finish shapes to save on final tooling costs. All of our forgings can go through hot die forging, rough machining, heat treatment and other processes, and the forgings can be finished to reach the final assembly condition.

Contact Now

Our baohua business enterprise is a kingdom-owned to non-public organization. the own family enterprise has a history of greater than 60 years, from the initial forging iron portions to the current hard processing, heat remedy and finishing of forgings. gadgets and device also intently comply with the requirements of present day product production. at present, there are extra than 80 processing gadget, in addition to zeiss cmm, japanese small board profiler, gear detector, ω mega tool setting tool and different inspection and detection gadget.

Contact Now

The higher quality and higher strength and wear of this product's forged gear bracelet is achieved through shaped grain flow, reduced grain size and thermal processing. Thereby, the mechanical properties and metallurgical stability of the open-die forging process are improved. All of our forgings can go through hot die forging, roughing, heat treatment, etc.

Contact Now

Flange has the blessings of high electricity, excellent sealing, handy upkeep, robust adaptability and reusability, which makes it an essential and essential factor in pipeline system. the subsequent is the product records. MATERIAL4130-75KHARDNESS207-237INNER DIAMETER57.76OUTSIDE DIAMETER304.65Our baohua business enterprise turned into based in 1969. after three generations' tough paintings, it now covers an area of fifty,000 ㎡ and has a building vicinity of 25,000 ㎡. there are 260 employees and forty six engineering technicians. the once a year output of forgings is 30,000 lots.

Contact Now