The joint seats produced by our company are mainly used in wind power generation industry. Raw materials are purchased from hot rolled round steel or steel ingots recognized at home and abroad. We can carry out hot forging according to customers' requirements, and meet the requirements of ultrasonic flaw detection (UT). Forging can improve product performance and save costs.

Contact Now

After heating and repeated forging, it may additionally be modulated and warmth dealt with and completed in keeping with purchaser requirements. After repeated forging, the forging ratio has excessive forging ratio and top durability, that's appropriate for key components of equipment.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 60kg-7000kg, Forging needs to be completed through heating, pre-forging, forming and other processes.The die movement and degree of freedom of the forging equipment are inconsistent. According to the deformation limitation characteristics of the lower dead center, the forging equipment can be divided into the following four forms:1.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, and other processes.The die movement and degree of freedom of the forging equipment are inconsistent. According to the deformation limitation characteristics of the lower dead center, the forging equipment can be divided into the following four forms:1.

Contact Now

Our products at Bauer are based on manufacturer-provided flexibility in shape, size and material, lower volume requirements and near-finished shapes that save on final processing costs. And all our forgings can go through hot die forging, rough machining, heat treatment and other processes, and the forgings can be finished to reach the final assembly condition. Our company has API certificate and SQ1 certificate and has many years of experience in petroleum product processing.We support mass production, and the quotation of products can be communicated according to the market price.

Contact Now

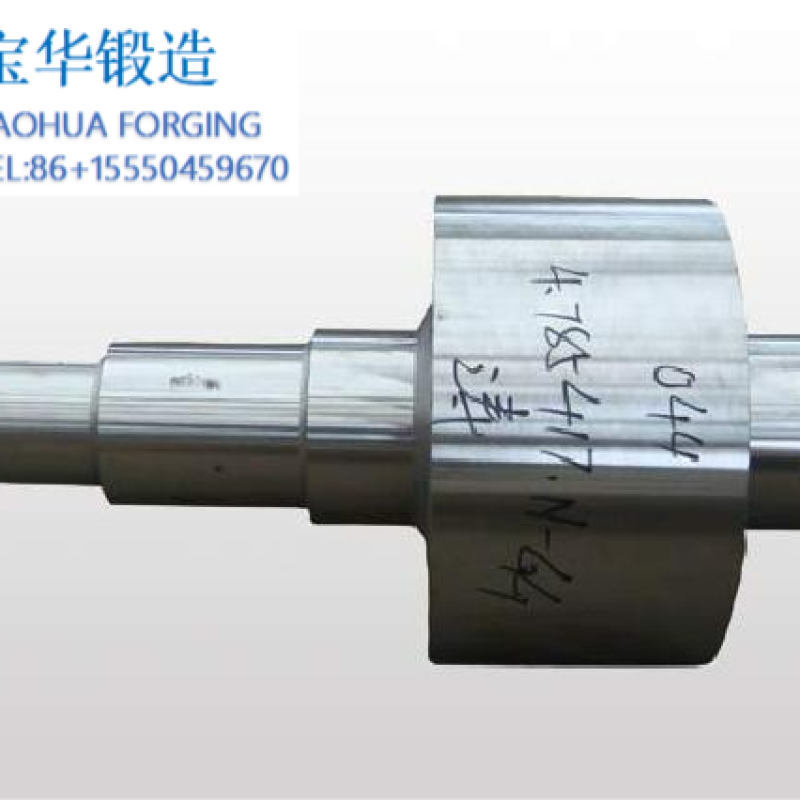

The driving shaft forgings produced by our company are mainly used in construction machinery industry, petroleum industry and wind power industry. The raw materials are hot rolled round steel or ingot recognized at home and abroad. According to customer's requirements, we can carry out hot forging and forming, and meet the requirements of ultrasonic testing (UT). Forging can improve product performance and save cost.

Contact Now

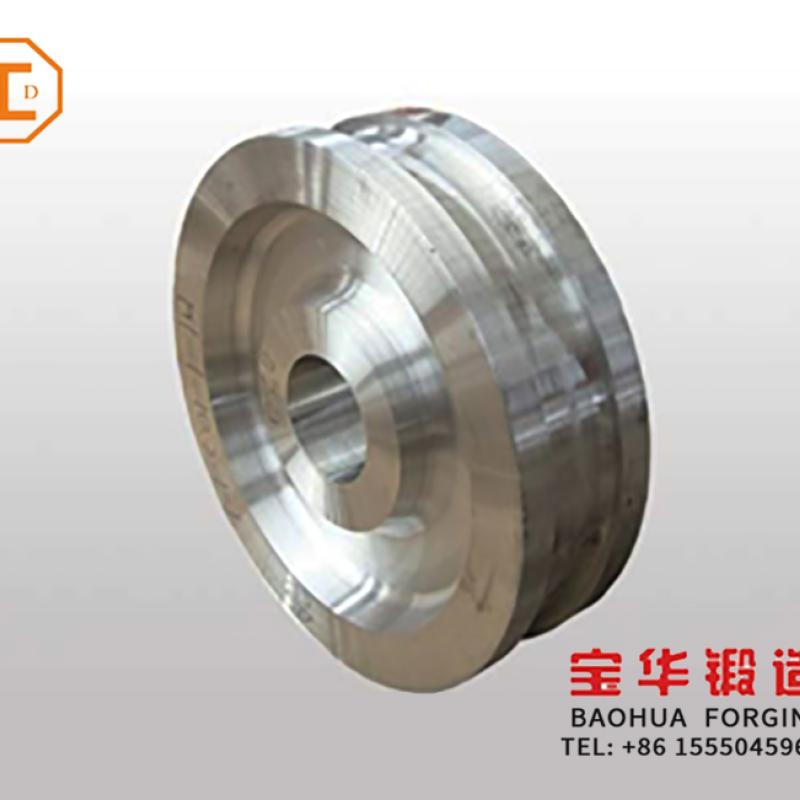

The higher quality and higher strength and wear of this product's forged gear bracelet is achieved through shaped grain flow, reduced grain size and thermal processing. Thereby, the mechanical properties and metallurgical stability of the open-die forging process are improved. All of our forgings can go through hot die forging, roughing, heat treatment, etc.

Contact Now

The completed threaded flange we produce may be processed by using hot-die forging, difficult operating, warmth remedy and different approaches, thus growing the forging ratio and performance stability. Completed threaded flange can be similarly processed to acquire very last meeting conditions.The corporation uses a continuing rolling ring technique, which ends up in more solid product performance and greatly decreased weight and value financial savings.

Contact Now

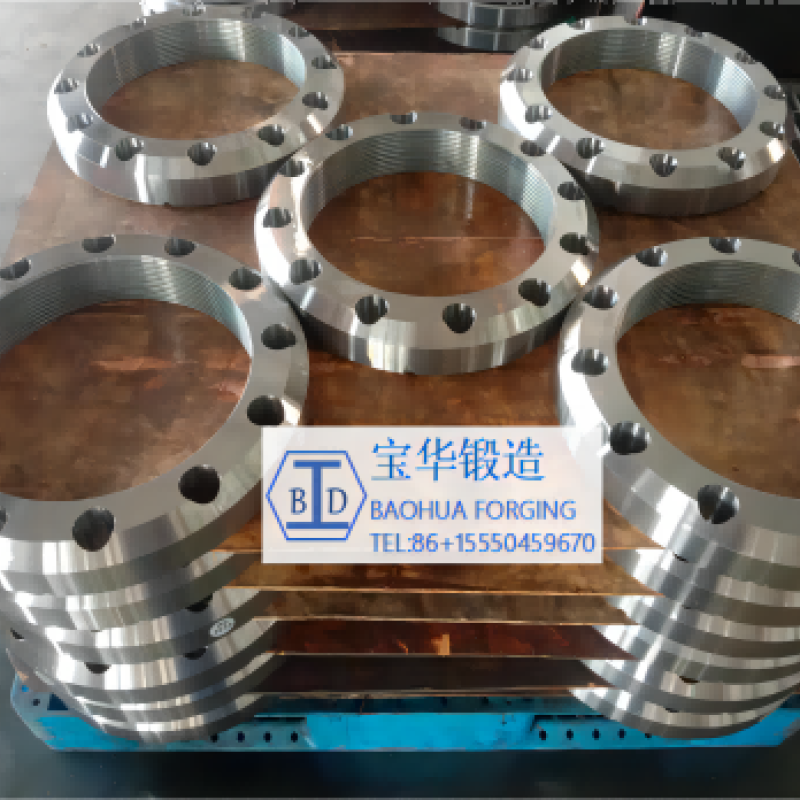

Our company uses the seamless rolling ring process, which makes the product more stable and can greatly reduce the weight of blanking and save cost. Forged flanges can be made of a wide range of materials including but not limited to 4140, 4130, 35CrMo, 20CrMnMO and can be forged and machined in a wide range of sizes and sizes ranging from 200mm to 3000mm in diameter.All of our forgings can be forged by hot-die forging, rough working, heat treatment and other processes, increasing the forging ratio and performance stability.

Contact Now

The employer can produce in batches. after hot die forging, difficult machining, warmness remedy and different tactics, the forging ratio and overall performance balance are elevated, and the fee is stored. In step with client necessities, 4140, 4130, 45 #, 40cr, 30crmo, 35crmo, 42crmo, 18crnimo7-6 and other substances may be made. forging can be finished on distinctive forging device gadgets in line with distinctive weights. the weight of cast merchandise can reach 6kg-2000kg.

Contact Now

According to the model of this product, the die and forging are integrated, and mass production is executed. thereby decreasing prices and excessive performance. and our business enterprise can use various varieties of substances inclusive of: 4140, 35CrMo, 42CrMo, forty five#, 4130 and so forth. after repeated pre-forging through heating, after die forging, the forging ratio is high and the sturdiness is good, that is suitable for the important thing components of the gadget. 1.

Contact Now

Our company employs a new seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requirements and near-finish shapes to save on final tooling costs. All of our forgings can go through hot die forging, rough machining, heat treatment and other processes, and the forgings can be finished to reach the final assembly condition.

Contact Now

Shaft: one of the main parts in machinery. Generally, it is a metal round rod around which wheels and other rotating parts rotate or follow it.As a big category, shafts are subdivided into intermediate shafts, crankshafts, driving shafts, etc.The intermediate shaft forgings produced by our company are mainly used in construction machinery industry, petroleum industry and wind power industry. The raw materials are hot rolled round steel or ingot recognized at home and abroad.

Contact Now

BAOHUA produces solid gear, ring gear shapes for single, double and different close to internet shapes for completing into numerous unique shapes.OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsThese forged gear shapes may be crafted from ferrous and non-ferrous metals which include carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and device steel.Forging gear and ring gear blank processBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower

Contact Now

In the production of high neck flange, the flange is formed by hot pressing or cold pressing, including the processing of screw holes and the opening of the flange.During the inspection, the welded flange is inspected, such as pressure test, chemical composition analysis, magnetic particle inspection, etc., to ensure its quality meets the requirements.Finally, in the surface treatment, the flange can be treated with zinc plating, spraying and electroplating to enhance its corrosion resistance and aesthetics.Product Details:Material4130-75kHardness207-237Inner Diameter52.7Outside Diameter311Our

Contact Now

BAOHUA produces forged gear, ring gear shapes for single, double and other near net shapes for finishing into several different shapes. OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsThese forged gear shapes can be made from ferrous and non-ferrous metals including carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and tool steel.Forging gear and ring gear blank processBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requir

Contact Now

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment and for the connection between two equipment. There are holes in the flanges, and bolts make the two flanges closely connected.MATERIAL4130-75KHARDNESS207-237INNER DIAMETER635OUTSIDE DIAMETER812.8Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians.

Contact Now

Our company can independently design and process forging dies according to the drawings, and has many years of experience in forging planetary carriers. The weight of the forged planet carrier product can reach 6kg-400kg, and the forging needs to be completed through heating, pre-forging, forming, trimming and other processes.

Contact Now

Our business enterprise can independently layout and system forging dies in keeping with the drawings, and has many years of experience in forging planetary carriers. the burden of the cast planet provider product can attain 6kg-400kg, and the forging needs to be completed via heating, pre-forging, forming, trimming and other strategies.

Contact Now

For the production of bearing seat products, our company can make many kinds of materials, such as 45, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 according to customer requirements. In addition, our company independently develops the forging process of two-die cavity, which can greatly reduce the weight of blanking and thus greatly improve the forging efficiency. In addition, forging can be carried out on different forging equipment units according to different weights. The forged product can reach 6 kg-500 kg.

Contact Now

According to your needness, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.1. Free forging.

Contact Now

Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. And has ISO 9001, API 20b and API Q1 certificates.The forging equipment of our Baohua company mainly includes: five tons and three tons of free forging hammers, 2500 tons, 1000 tons and 600 tons of friction presses, six large splint hammers and various types of air hammers, and 1000 tons of multi-directional die forging presses.

Contact Now

Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. And has ISO 9001, API 20b and API Q1 certificates.The forging equipment of our Baohua company mainly includes: five tons and three tons of free forging hammers, 2500 tons, 1000 tons and 600 tons of friction presses, six large splint hammers and various types of air hammers, and 1000 tons of multi-directional die forging presses.

Contact Now

Our enterprise can independently layout and method forging dies consistent with the drawings, and could try our first-rate to store forging materials. the burden of the solid product can attain 60kg-5000kg, and the forging needs to be finished thru heating, pre-forging, forming and other processes. numerous materials inclusive of 42CrMo, 4140, 4130, 40cr, 20CrMnMo, 18CrNiMo7-6, 410ss can be solid. our employer has APIcertificates and SQ1 certificates and has many years of revel in in petroleum product processing.The casing head is usually made of 35 or 42 Cr Mo alloy structural steel.

Contact Now