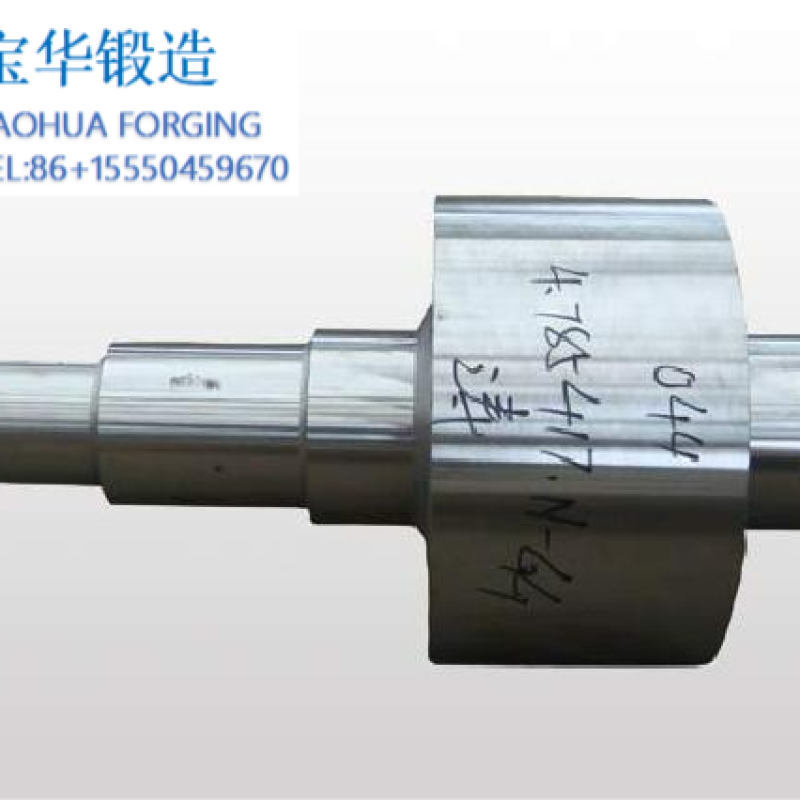

The driving shaft forgings produced by our company are mainly used in construction machinery industry, petroleum industry and wind power industry. The raw materials are hot rolled round steel or ingot recognized at home and abroad. According to customer's requirements, we can carry out hot forging and forming, and meet the requirements of ultrasonic testing (UT). Forging can improve product performance and save cost.

Contact Now

Our Baohua company is able to independently design and develop the die, which makes the torque arm forge in one shape, saves material greatly and improves the stability of the product. Moreover, Baohua has the finishing ability, which can cover many processes such as forging, machining, heat treatment, finishing and so on. Finally, the finished product can be delivered. And we can deliver according to customer needs in different delivery states. The torque arm is a suspension component mounted on the rear drive axle of rear wheel drive vehicles.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 15kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.The Supporting Shaft Component Structure and bobbin collet shaft device of filament winding machine discloses a supporting shaft component structure and bobbin collet shaft device of filament winding machine.

Contact Now

The output tools shaft synthetic by means of us can be product of forty five#, 40cr, 30crmo, 35crmo, 42crmo, 18crnimo7-6 and other substances according to consumer requirements. it can be forged on different forging device gadgets in step with one-of-a-kind weights. the forging product weight can attain 6kg-500kg. the forging method wishes to be finished by means of heating, pre-forging, forming and trimming.According to the different shapes of axes, shafts can be divided into crankshaft and straight shaft.

Contact Now

Our Baohua company has mold design engineers who can provide drawings according to customersIndependently designed and developed the mold, making the fixed shaft locking sleeve integrally forged, greatly saving materials, and improving the stability of the product. In addition, our company has the ability of finishing, which can cover multiple integrated processes such as forging, machining, heat treatment and finishing, and can finally achieve the delivery of finished products.

Contact Now

There are no special requirements for the material of the supporting shaft. In the process of production, manufacturers mainly produce according to their actual availability. Basically follow the following principles:1. Select the materials for manufacturing the supporting shaft according to the use of the main parts. If it is used for support, it should be made of materials that can bear the support. If it is used for fixing, it is necessary to select materials that are convenient for welding the support shaft and the fixing point.2.

Contact Now

Selection of positioning datumThe machining sequence of the main surface of the gear shaft largely depends on the selection of the positioning datum. The structural characteristics of shaft parts and the position accuracy requirements of the main surface of the spindle determine that taking the axis as the positioning datum is the most ideal. This not only ensures the unity of the datum, but also makes the positioning datum coincide with the design datum. Generally, the outer circle is the coarse datum, and the sharp holes at both ends of the shaft are the fine datum.

Contact Now

Our manufactured output gear shaft can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials according to customer requirements. Forging can be carried out on different forging equipment units according to different weights. The forged product can weigh up to 6kg-500kg. The forging process needs to be completed by heating, pre-forging, forming and trimming. All these processes are integrated by our Baohua Company, thus ensuring the quality of products.In the design, the application of gear shaft generally involves the following situations:1.

Contact Now

The middle shaft is a cylindrical object that passes through the middle of a bearing, wheel or gear, but a few of them are square. The middle shaft is a mechanical part that supports the rotating part and rotates with it to transmit motion, torque or bending moment. Generally, it is a metal round bar, and each section can have a different diameter. In the machine, the rotating parts are mounted on the shaft.The intermediate shaft forgings produced by our company are mainly used in equipment accessories of construction machinery industry, petroleum industry and wind power generation industry.

Contact Now

Output gear shaft, according to customer requirements can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials, according to the weight of different forging equipment units for forging, the weight of forged products can be To reach 6kg-500kg, forging needs to be completed through heating, pre-forging, forming, trimming and other processes.Customers in any industry using output gear shafts can request a quote for any quantity of forged gear shafts, from one prototype at a time and small batches to high volume production.

Contact Now

Our company has ISO-9001 certificate, and the production of supporting shaft is integrally forged with a corresponding model of die forging hammer, with high efficiency and low cost. And various types of materials can be used, such as 42CrMo, 45#, 35CrMo, 4140, 4130, etc. After repeated heating pre-forging and die forging, the forging ratio is high and the durability is good. It is suitable for fitting installation of engineering machinery and wind power industry equipment.

Contact Now

The pitch gear shaft mechanism of wind power equipment controls the position angle of blades relative to the rotation plane. Small-sized fans do not have a pitch control mechanism, so they need to rely on stall to adjust the speed at high speed. Pitch control enables the fan to obtain electric energy at low wind speed, and intercept fixed wind energy when the wind speed is greater than the rated wind speed. There is more than one method to control the pitch angle; All methods need a mechanism to control the angle of the blade.

Contact Now

According to your needness, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.1. Free forging.

Contact Now

The piston head in the oil field refers to a part of the oil recovery pump, which is used to pump liquid (such as oil) from the bottom of the well to the ground. It usually consists of piston, piston rod and spring. When the driving machine (such as motor) starts, it will drive the pump rod, thus making the piston move back and forth in the pump body.

Contact Now

These hollow shaft may be crafted from ferrous and non-ferrous metals which include carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and device steelBAOHUA produces solid gear, ring gear shapes for single, double and different close to internet shapes for completing into numerous unique shapes.OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requirements and near-finished shapes t

Contact Now

Shaft: one of the main parts in machinery. Generally, it is a metal round rod around which wheels and other rotating parts rotate or follow it.As a big category, shafts are subdivided into intermediate shafts, crankshafts, driving shafts, etc.The intermediate shaft forgings produced by our company are mainly used in construction machinery industry, petroleum industry and wind power industry. The raw materials are hot rolled round steel or ingot recognized at home and abroad.

Contact Now

The cylinder head in engineering usually refers to the cylinder head of the engine. Engine is the core power device of all kinds of construction machinery, and cylinder head is an important part of engine.Hydraulic cylinder is a common executive component in construction machinery, which is used to produce linear motion or drive other equipment.

Contact Now

For the forging and casting of screw tee, our Baohua Company mainly focuses on forging. Customers can make requests according to their own needs, and we will carry out forging production according to the drawings provided. Like simple and numerous products, our company's mold engineers improve the production speed and accuracy of products by building molds. For our enterprise itself, from the state-owned to the individual, it has gone through three generations of family management, and the equipment is constantly updated.

Contact Now

The manufacturing process of the support shaft roughly includes the following steps:1. Material preparation: Select suitable raw materials for processing, usually steel or cast iron.2. Processing and manufacturing: According to the design drawings of the support shaft, the raw materials are processed and manufactured by using lathes, milling machines, drilling machines and other machines. The machining process mainly includes turning, drilling, tapping, grinding, etc., so as to make various parts of the supporting shaft.3.

Contact Now

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

Contact Now

The torque arm on wind power refers to the part between the main shaft of the wind turbine and the rotor of the generator, which converts the torque transmitted by the rotating main shaft into the power that the generator drives the rotor to rotate, thus generating electric energy.The torque arm produced by our company is mainly used as accessories for wind power generation equipment. Raw materials are purchased from round steel with recognized quality at home and abroad.

Contact Now

For the manufacturing of Crusher Long Hammer products, our agency is capable of independently design dies and forge according to product specifications. cloth type and weight can also be produced in line with client requirements.

Contact Now

We have many years of certificates such as AIP Q, and we are also very skilled in producing related products such as bar heads.According to the model of this product, the die and forging are integrated, and mass production is executed. thereby decreasing prices and excessive performance. and our business enterprise can use various varieties of substances inclusive of: 4140, 35CrMo, 42CrMo, forty five#, 4130 and so forth.

Contact Now

Torque arm in wind power refers to an important structural part of wind turbine, which is used to convert wind energy into electric energy. The rotor of wind turbine usually includes impeller (blade), shaft and torque arm.

Contact Now