Baohua employer has the ability of independently designing molds, and may forge according to unique product specifications. substances and weights may be made in step with distinctive consumer necessities.

Contact Now

Baohua employer has the talent of independently designing molds, and may forge consistent with special product specifications. substances and weights may be made consistent with exclusive customer requirements.

Contact Now

For the forging and casting of screw tee, our Baohua Company mainly focuses on forging. Customers can make requests according to their own needs, and we will carry out forging production according to the drawings provided. Like simple and numerous products, our company's mold engineers improve the production speed and accuracy of products by building molds. For our enterprise itself, from the state-owned to the individual, it has gone through three generations of family management, and the equipment is constantly updated.

Contact Now

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

Contact Now

The completed threaded flange we produce may be processed by using hot-die forging, difficult operating, warmth remedy and different approaches, thus growing the forging ratio and performance stability. Completed threaded flange can be similarly processed to acquire very last meeting conditions.The corporation uses a continuing rolling ring technique, which ends up in more solid product performance and greatly decreased weight and value financial savings.

Contact Now

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

Contact Now

Our company independently designs dies and forges according to product specifications. Material types and weights can be made according to customer requirements. This gear company independently designed the die to achieve precision forging, so that the material utilization rate reaches more than 90%, which greatly saves the cost. Our company also has roughing, heat treatment and finishing, which can be delivered according to customer requirements in different delivery states.

Contact Now

This product can be repeatedly forged after heating, and can also be modulated and heat treated and finished according to customer requirements. After repeated forging, the forging ratio is high and the durability is good. It is suitable for key parts of equipment. For casing heads, our company can forge 10kg-5000kg forgings, and can forge a variety of materials including 42CrMo, 4140, 4130, 40Cr, 20CrMnMo, 18CrNiMo7-6, 410SS.

Contact Now

With regard to inner ring end cap, we can make many kinds of materials according to customer requirements, such as 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc. Our company independently develops ring forging process, which can greatly improve forging efficiency and reduce blanking weight, and ultimately achieve the purpose of cost saving. According to the weight, forging is carried out on different forging equipment units. The weight of forged products can reach 6kg-2000kg. The forging process needs to be completed by heating, pre-forging and forming.

Contact Now

As a mechanical part that stops or slows down the moving parts in the machine, the brake shell can be produced according to the materials required by customers in the production process. At present, our Baohua Company uses 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc., which are widely used. The processing of the brake shell needs to be completed by heating, pre-forging, forming, trimming and other processes. According to different weights, the forged products can be forged on different forging equipment units, and the weight of forged products can reach 6kg-500kg.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-7000kg, forging needs to be completed through heating, pre-forging, forming and other processes.

Contact Now

When we are producing cylinder head products, Baohua Company will produce products according to different materials according to the requirements specified by customers. For example: 45 #, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc.In addition, our company conducts forging on different forging equipment units according to different weights. The weight of forged products can reach 6kg - 500kg. Forging needs to be completed through heating, pre forging, forming, trimming and other processes.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 60kg-7000kg, Forging needs to be completed through heating, pre-forging, forming and other processes.The die movement and degree of freedom of the forging equipment are inconsistent. According to the deformation limitation characteristics of the lower dead center, the forging equipment can be divided into the following four forms:1.

Contact Now

According to your needness, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.1. Free forging.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, and other processes.The die movement and degree of freedom of the forging equipment are inconsistent. According to the deformation limitation characteristics of the lower dead center, the forging equipment can be divided into the following four forms:1.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 15kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.The Supporting Shaft Component Structure and bobbin collet shaft device of filament winding machine discloses a supporting shaft component structure and bobbin collet shaft device of filament winding machine.

Contact Now

Our business enterprise can independently layout and system forging dies in keeping with the drawings, and has many years of experience in forging planetary carriers. the burden of the cast planet provider product can attain 6kg-400kg, and the forging needs to be completed via heating, pre-forging, forming, trimming and other strategies.

Contact Now

After heating and repeated forging, it may additionally be modulated and warmth dealt with and completed in keeping with purchaser requirements. After repeated forging, the forging ratio has excessive forging ratio and top durability, that's appropriate for key components of equipment.

Contact Now

We can make 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials according to customer requirements. According to different weights, we can forge on different forging equipment units. The weight of forged products can reach 6kg-500kg. It needs to be completed by heating, pre-forging, forming, trimming and other processes. The casing head is usually made of 35 or 42 Cr Mo alloy structural steel. There is also a casing hanger in the casing head, which is used to hang the casing string of corresponding specifications and seal the annulus. BOP stack shall be installed on it.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.The design of forged steel and the abrasive tools for its production require initial costs.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, 4140, 4130 and other materials. According to different weights, it can be forged on different forging equipment units, and the weight of the forged products can reach 6kg-5000kg, forging needs to be completed through heating, pre-forging, forming and other processes.Forging is a processing method that uses forging machinery to exert pressure on metal blank to make it produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes.

Contact Now

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.Flange is also called flange plate or flange. Flanges are the parts that connect pipes to each other and are connected to pipe ends. There are holes on the flange, and the bolts make the two flanges tightly connected.

Contact Now

Our company can independently design and process forging dies according to the drawings, and has many years of experience in forging planetary carriers. The weight of the forged planet carrier product can reach 6kg-400kg, and the forging needs to be completed through heating, pre-forging, forming, trimming and other processes.

Contact Now

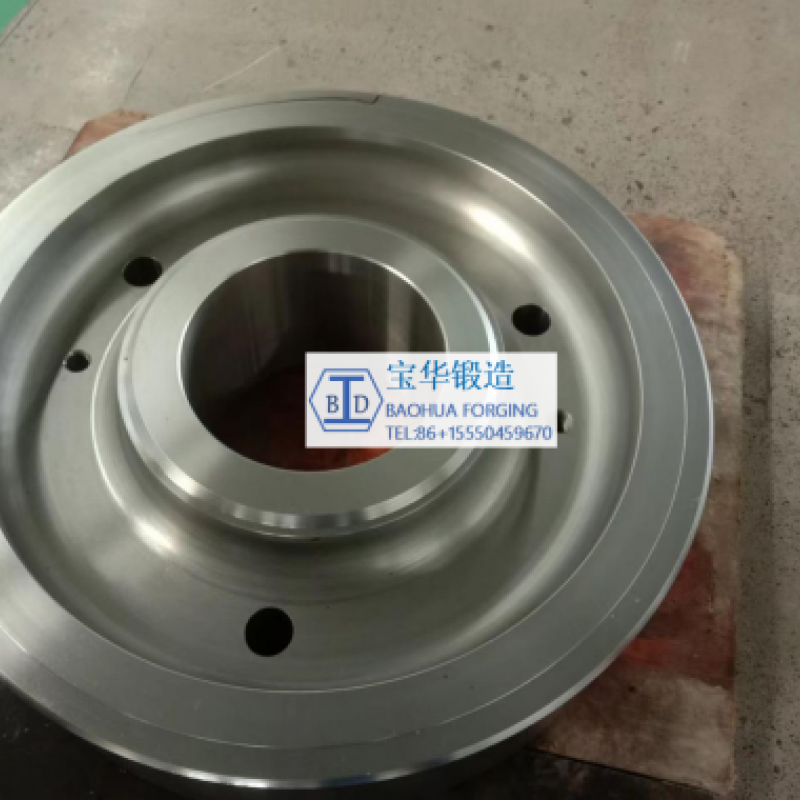

According to customer requirements, 4140, 4130, 45 #, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials can be made. Forging can be carried out on different forging equipment units according to different weights. The weight of forged products can reach 6kg-2000kg. Forging needs to be completed through heating, pre forging, forming, trimming and other processes to increase the forging ratio and stability of products. Flange forgings can be finished to meet the final assembly conditions.Threaded flange refers to a kind of flange which is connected with pipe by thread.

Contact Now