Bearing seat is a mechanical part used to put in bearings, which is normally fabricated from solid metallic, gray cast iron, solid aluminum alloy, forged copper and different substances. the bearing seat supports and locates the axis of rotation by means of solving and helping the bearing.

Contact Now

For the production of bearing seat products, our company can make many kinds of materials, such as 45, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 according to customer requirements. In addition, our company independently develops the forging process of two-die cavity, which can greatly reduce the weight of blanking and thus greatly improve the forging efficiency. In addition, forging can be carried out on different forging equipment units according to different weights. The forged product can reach 6 kg-500 kg.

Contact Now

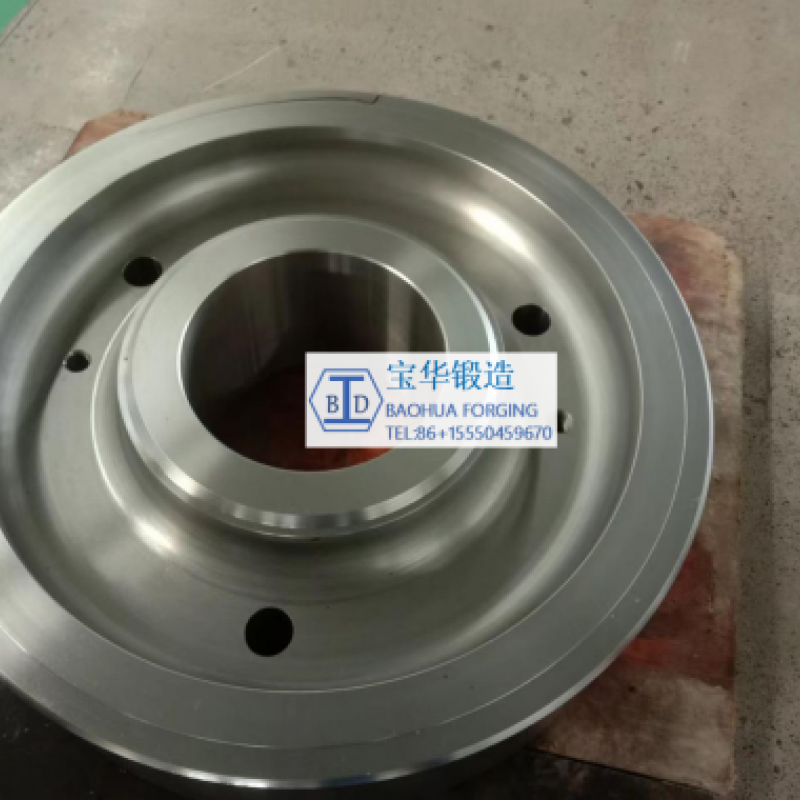

Bearing housing, also known as bearing housing or bearing frame, is a mechanical part used to support and fix bearings. It plays the role of fixing the bearing and supporting the rotating shaft in mechanical equipment, so that the bearing can operate normally and provide sufficient stability and protection under load and vibration conditions. Below are the product details.MATERIAL45#INNER DIAMETER380OUTSIDE DIAMETER460Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Contact Now

The bearing seat provides stable support, accurate positioning and sealing protection for the bearing, so that the bearing can operate normally and prolong its life. It is an indispensable part of mechanical equipment, which is of great significance for maintaining the normal operation of mechanical equipment and improving work efficiency.Below are the product details.MATERIAL45#INNER DIAMETER380OUTSIDE DIAMETER460Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Contact Now

Bearing housing, also known as bearing housing or bearing frame, is a mechanical part used to support and fix bearings. It plays the role of fixing the bearing and supporting the rotating shaft in mechanical equipment, so that the bearing can operate normally and provide sufficient stability and protection under load and vibration conditions. MATERIAL45#INNER DIAMETER280OUTSIDE DIAMETER520Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Contact Now

Bearing seat is a mechanical part used to fix bearings. Generally, it includes two parts: base and support. The base is composed of a platform and a flange, and the flange usually has fixing screw holes for fixing to the frame of machinery and equipment. Bearings are the mounting parts of bearings, usually made of cast iron or sheet metal, with brackets for mounting bearings and fixing screw holes. Bearing seat is usually made by casting or machining, which has high strength and durability and is widely used in various mechanical equipment.Our Baohua Company was founded in 1969.

Contact Now

Our Baohua company has mold design engineers who can provide drawings according to customersIndependently design and develop the mold, which makes the bearing seat forged into one, greatly saving materials, and improving the stability of the product. In addition, our company has the ability of finishing, which can cover multiple integrated processes such as forging, machining, heat treatment and finishing, and can finally achieve the delivery of finished products.

Contact Now

After heating and repeated forging, it can also be modulated heat treatment and finishing according to customer requirements, so after repeated forging, the forging ratio is high, the durability is good, and it is suitable for key accessories of equipment.

Contact Now

The bearings are divided into standard type, adjustable type, flange type and large opening type.Standard type: several techniques for installing with snap ring and fixed plate.

Contact Now

Slip seat, also known as sliding bearing sleeve, is a mechanical component used to support bearings and reduce friction in mechanical equipment.

Contact Now

The planet carrier is one of the main components of planetary gear transmission, and the planetary axle or bearing is mounted on the planet carrier. When the planetary gear is the basic component, it is the part of the mechanism that bears the greatest external torque.

Contact Now

The planetary transmission system has the advantages of compact structure, large transmission power, high bearing capacity, strong resistance to shock and vibration, and stable transmission, so it has a very wide range of applications. As one of the important components of the planetary transmission system, the dynamic meshing characteristics of the internal gear ring directly affect the load sharing and dynamic load performance of the transmission system.

Contact Now

The middle shaft is a cylindrical object that passes through the middle of a bearing, wheel or gear, but a few of them are square. The middle shaft is a mechanical part that supports the rotating part and rotates with it to transmit motion, torque or bending moment. Generally, it is a metal round bar, and each section can have a different diameter. In the machine, the rotating parts are mounted on the shaft.The intermediate shaft forgings produced by our company are mainly used in equipment accessories of construction machinery industry, petroleum industry and wind power generation industry.

Contact Now

Hangers produced by our company are mainly used in petroleum industry. Raw materials are purchased from round steel with recognized quality at home and abroad. We can forge the corresponding model of dies and hammers according to customers' requirements, thus improving production efficiency and saving time.

Contact Now

Our company is able to design the die according to the drawing according to the customer's requirements and achieve precision die forging, so that the utilization rate of rough rotor materials can reach more than 90%, which greatly saves costs. Our company can deliver according to the needs of customers with different delivery status. The quantity can also be purchased from one to more.Welcome customers to consult online.According to ISO standards, a rotating body supported by bearings is called a rotor.

Contact Now

Flange, additionally known as flange or flange. flange is a part of connecting shaft, which is used to connect pipe ends; it's also used for flanges at the inlet and outlet of device, and is used for the relationship among gadget, including decreasing pipe flanges. there are holes inside the flanges, and bolts make the two flanges closely connected. all connecting parts which are bolted round two planes and closed at the same time are usually known as "flanges", which includes the relationship of air flow pipes.

Contact Now

Our manufactured output gear shaft can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials according to customer requirements. Forging can be carried out on different forging equipment units according to different weights. The forged product can weigh up to 6kg-500kg. The forging process needs to be completed by heating, pre-forging, forming and trimming. All these processes are integrated by our Baohua Company, thus ensuring the quality of products.In the design, the application of gear shaft generally involves the following situations:1.

Contact Now

Our company independently designs dies and forges according to product specifications. Material types and weights can be made according to customer requirements. This gear company independently designed the die to achieve precision forging, so that the material utilization rate reaches more than 90%, which greatly saves the cost. Our company also has roughing, heat treatment and finishing, which can be delivered according to customer requirements in different delivery states.

Contact Now

Gear is a common mechanical transmission device, which consists of one or more gears. Product details are as follows:NAMEGEARMATERIAL18CrNiMo 7-6HARDNESS140-240INNER DIAMETER121OUTSIDE DIAMETER299.48Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Contact Now

Gear is a common mechanical transmission device, which consists of one or more gears. The finished gear is mainly made of 18CrNiMo7-6. After turning, milling, drilling, planing, rolling, shaving, grinding and heat treatment. Further finish machining from primary machining. Details of this product are as follows:Product NameGear FinishedMaterial18CrNiMo7-6HARDNESS140-240INNER DIAMETER210OUTSIDE DIAMETER611Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Contact Now

Our unbiased research and improvement of double-hollow space forging procedure in baohua enterprise can significantly enhance the forging performance and decrease the blanking weight, and subsequently obtain the reason of fee saving. in line with unique weights, forging can be completed on distinctive forging gadget units, and the load of forged merchandise can attain 6kg-500kg. forging needs to be finished by means of heating, pre-forging, forming, trimming and different tactics.

Contact Now

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment, and is used for the connection between two equipment, such as reducing pipe flanges. There are holes in the flanges, and bolts make the two flanges closely connected. All connecting parts that are bolted around two planes and closed at the same time are generally called "flanges", such as the connection of ventilation pipes. Such parts can be called "flange parts".

Contact Now

Flange, also known as flange or flange. Flange is a part of connecting shaft, which is used to connect pipe ends; It is also used for flanges on the inlet and outlet of equipment and for the connection between two equipment. There are holes in the flanges, and bolts make the two flanges closely connected.The flanges we process and produce are mainly used in petroleum and construction machinery and equipment industries. The materials used in processing and production are flexible and can be forged according to the shape and size provided by customers.

Contact Now

The cylinder head produced via our baohua business enterprise can be made of different substances in line with purchaser necessities. substances consisting of 45 #, 40cr, 30crmo, 35crmo, 42crmo, 18crnimo7-6, and so on. further, baohua agency has independently developed the double hollow space forging procedure, which could greatly enhance the forging efficiency and reduce the blanking weight, and in the long run gain the intention of value saving. forging is achieved on distinct forging equipment devices according to special weights. the weight of solid products can attain 6kg-500kg.

Contact Now